Aside from providing essential information and instructions, labeling plays a vital role in making products stand out and increasing brand retention. There are two types of labels: primary and secondary. Primary labels are crafted to draw consumers’ attention; these commonly include high-quality images and colors to increase their appeal, capture buyers’ eyes, and represent the company’s brand. On the other hand, secondary labels are supplemental — found on the back and contain valuable product information.

Kiss cutting is one of the most popular methods for creating pressure-sensitive labels, stickers, and decals. It is a common manufacturing technique that involves leaving the finished part on a removable layer of paper or foil. This layer then holds the part until it is peeled off and used, making it ideal for practical uses.

This article will explore how the kiss-cutting process is used in creating labels, stickers, and decals and their applications in various industries.

Kiss Cutting For Labels, Stickers, And Decals

Kiss cutting offers more convenience than other methods because it only requires the removal of a part from a large back sheet. Thus, it is more effortless than peeling the backing off a similar-sized part. It also allows the assembly of several finished parts onto a single backing layer if the goal is keeping many parts together.

When using kiss cutting to create stickers, vinyl plotters are made to “kiss” the top adhesive layer of a sticker sheet. The plotter perceives how much pressure must be applied to keep the paperback intact and undamaged. Unlike a die-cut sticker with no paper border, kiss cutting labels and stickers have a paper border around and behind them.

In addition, the kiss-cut sticker sheet allows for both similar-shaped and sized stickers and different ones. This is the reason why kiss cutting is popular for producing a large number of stickers on a single sheet. As long as the shapes fit on the page, the number of stickers does not matter.

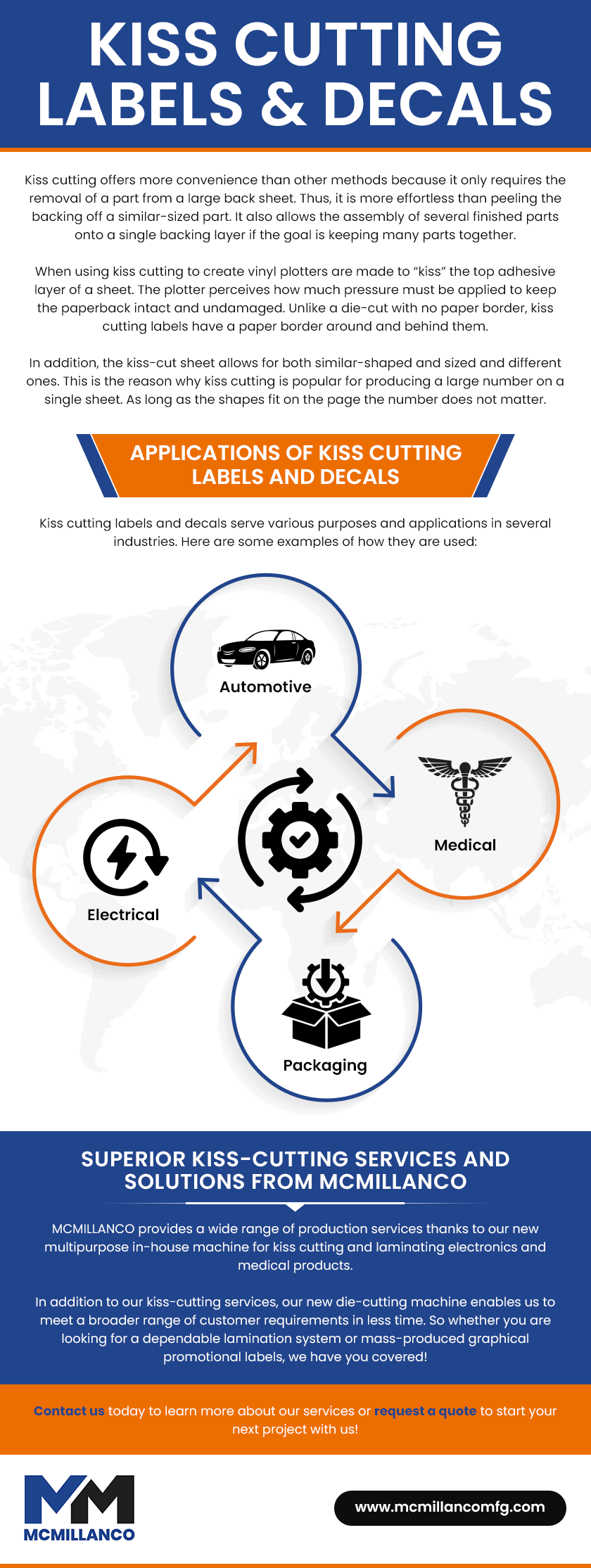

Applications Of Kiss Cutting Labels, Stickers, And Decals

Kiss cutting labels, stickers, and decals serve various purposes and applications in several industries. Here are some examples of how they are used:

Automotive

Automotive labels are made up of badging (stickers on the vehicle’s exterior identifying its model and features) and labels (barcode, estimate, and VIN labels). They usually display component information, the company’s name and logo, technical specifications, and other important details. The following are the commonly used stickers and labels in the automotive industry:

- Auto label categories by end-use (asset, branding, warning, dome labels)

- Auto label categories by identification method (barcode, radio-frequency identification)

- Auto label categories by application process (glue-applied, heat transfer)

- Auto label categories by vehicle component application (chassis, engine components)

Medical

Healthcare labels are applied to a wide range of medical products, such as bottles, containers, vials, devices, and more. They convey critical information on instructions, warning signs, barcodes, evaluations, and variable information printing (VIP). The following are some common uses of labels and stickers in the medical industry:

- Vials, syringes, and ampules

- Over-the-counter medicines and pills

- Concealing labels for clinical trials

- Blood and plasma labels

- Cryogenics and cold-chain products

Packaging

Packaging is a significant part of the appeal for various kinds of merchandise in multiple industries. The vibrant colors and sharp graphics printed on different materials help in giving specific types of products identity and character. The most important labels and stickers that must be attached to the product include the following:

- Manufacturer

- Expiry date

- Ingredients

- Product instructions

- Product certifications

- Trademarks

Electrical

Electrical safety stickers give detailed instructions for the operation and handling of electrical equipment, such as instructing workers on operating the equipment safely or not using damaged or malfunctioning equipment. Some examples of electrical safety labels and stickers are as follows:

- Conduit and voltage labels

- Energy source identification stickers

- Arc flash warnings

- Panel identification

- Transformer labels

Superior Kiss-cutting Services And Solutions From Mcmillanco

MCMILLANCO is a jack of all trades when it comes to manufacturing parts. We provide a wide range of production services thanks to our new multipurpose in-house machine for kiss cutting and laminating electronics and medical products.

In addition to our kiss-cutting services, our new die-cutting machine enables us to meet a broader range of customer requirements in less time. So whether you are looking for a dependable lamination system or mass-produced graphical promotional labels and stickers, we have you covered!

Contact us today to learn more about our services or request a quote to start your next project with us!