When we buy consumer products, we tend to read the labels for more product information. Manufacturers nowadays prefer to use adhesive or sticker labels to make their labeling more efficient and appealing. Printing industries use different machines to produce adhesive tags or stickers for art, sealing or packing, marketing, and advertising, to showcase a brand’s personality and consistently attract customers.

Kiss cutting is one of the processes in making mass-produced graphical promotions or stickers. This article will tackle what kiss cutting is all about and what materials can be used for this method.

What Is Kiss Cutting, And How Does It Work?

Kiss cutting is a great way to add style, purpose, and intrigue to your printed materials. Imagine how you peel off stickers – you get the designed part and discard the film it is attached to, then decorate the sticker to your mug, laptop, or notebook; that sticker you peeled off is an example of a kiss-cut finished product.

Kiss cutting is a method of cutting into a flat layered material where the top part is pierced, but the back layer is left intact. The term “kiss” refers to how the blade touches the upper layer of the material and leaves a pattern or cut with sufficient force to peel the top but not too forceful to cut through the backside. The blade gently “kisses” only the second layer and does not cut through it.

Is Kiss Cutting The Same As Die Cutting?

Kiss cutting is technically a die cutting method, and die cutting refers to using a machine to mass-produce cut-out shapes. Although their process is the same, and their outputs appear to be closely identical, they have a very slight difference. Unlike kiss cutting, which only cuts on the top layer, die cutting is like a cookie cutter that precisely cuts specific shapes straight to your materials’ top and bottom layers.

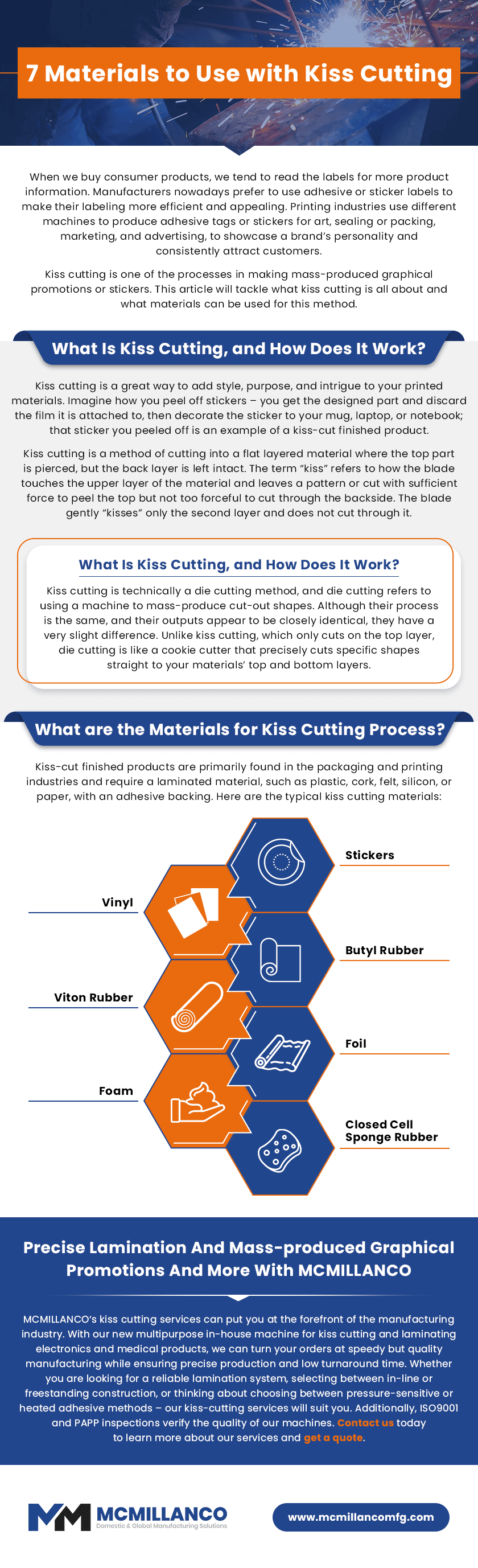

What Are The Materials For Kiss Cutting Process?

Kiss-cut finished products are primarily found in the packaging and printing industries and require a laminated material, such as plastic, cork, felt, silicon, or paper, with an adhesive backing. Here are the typical kiss cutting materials:

Stickers

Stickers are the most common kiss-cut material and are often seen on smooth surfaces such as vinyl, paper, plastic, some fabrics, or other adhesive-backing media, which have been printed and kiss-cut. They can be used as brand indicators, stamps, car and toy stickers, product labels, and annual license plate stickers.

Vinyl

Vinyl is a familiar kiss cutting material that can endure the heat in the kiss cutting process. Many businesses and clients prefer this material for its superior durability compared to other kiss cutting materials. Industrial vinyl kiss cutting uses computer-controlled machinery with a coarse roller to track the feeding process in a conveyor feed system.

Butyl Rubber

Butyl rubber material can absorb shock and vibration, block light, and serve as a seal. It is commonly used for gaskets because it is tear-resistant, less porous, and remains flexible at sub-zero temperatures. Kiss-cut gaskets can be rolled up like paper towels, making them easy to handle and dispense. Peeling the designed, cut part off the liner is considerably faster to perform, thus, enabling production efficiency.

Viton Rubber

Like butyl rubber, the viton rubber material is used for gaskets. However, it is more high-grade and is ideal for extreme applications due to its excellent sealing capabilities against gases and chemicals like those used within the oil and gas industry. It offers perfect sealing performance against petrochemicals, hydrocarbons, and acids. Viton can be manufactured as single or double-sided adhesive gaskets, with a finger lift or a tabbed liner if required, to ensure easy assembly.

Foil

Foil kiss cutting requires more care and precision than other kiss cutting materials because of the sensitivity and flexibility of the foil material. Foil’s lustrous quality contributes to its upscale appearance, making it an ideal material for promotional stickers or wine and cosmetic product labels.

Foam

Foams are well-known for their ease of formability, which comes in handy for effortlessly kiss cutting them to an exact desired dimension, shape, and size. Kiss-cut foam parts are peel-and-stick products equipped with pressure-sensitive adhesives that are flexible. They can come in tidy rolls, as the backing paper protects the kiss-cut foam parts from deforming during transit. Kiss-cut foam can also improve productivity and faster assembly while reducing the cost of production.

Closed Cell Sponge Rubber

Expanded rubber is the simplified term for closed cell sponge rubber. It contains balloon-like cells filled with nitrogen gas, which block the flow of air, water, and chemicals at low pressures. It is ideal to use as gaskets. Appliances, automobiles, construction, sports equipment, electrical enclosures, HVAC, marine, lighting, and more use closed cell sponge rubber gaskets. Closed cell sponge rubber can have an adhesive backing and are resilient, high-temperature stable, and inert. They come in soft, medium, firm, and extra firm and can be customized in many colors.

Precise Lamination And Mass-produced Graphical Promotions And More With Mcmillanco

MCMILLANCO‘s kiss cutting services can put you at the forefront of the manufacturing industry. With our new multipurpose in-house machine for kiss cutting and laminating electronics and medical products, we can turn your orders at speedy but quality manufacturing while ensuring precise production and low turnaround time. Whether you are looking for a reliable lamination system, selecting between in-line or freestanding construction, or thinking about choosing between pressure-sensitive or heated adhesive methods – our kiss-cutting services will suit you. Additionally, ISO9001 and PAPP inspections verify the quality of our machines. Contact us today to learn more about our services and get a quote.