Electronics Solutions from MCMILLANCO

MCMILLANCO has a range of solutions for the electronics market. Our fully integrated services span product concept, design, and engineering, custom converting services, manufacturing and logistics, and warehouse management.

We offer services that support electronic applications including PCBs, cellular and personal computing devices, appliance and industrial equipment electronics, touch screens, vehicle electronics, and more.

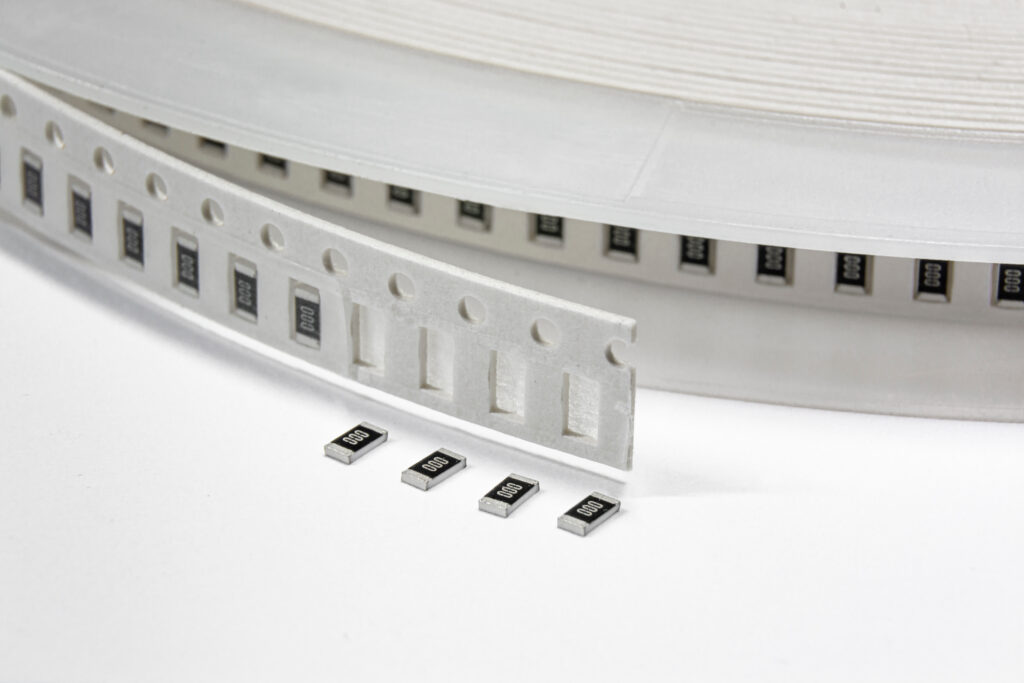

Converting

Converting is a fully automated manufacturing process for cutting and laminating thin sheets of material to make predetermined shapes through die cutting or kiss cutting. A specialized machine feeds the material from sheets or rolls as a die or other cutting tool stamps or cuts the shapes. Pieces are separated from the scrap material and then collected in a bin or re-rolled for end use, depending on the application.

Our equipment can work with a range of material widths and thicknesses in single layers or we can assemble a custom, multi-layer material to your specifications. Custom materials can then be die or kiss cut into desired shapes. Some common materials for electrical applications include, but are not limited to:

Converting is a highly versatile process for manufacturing items used in electrical devices and products with electrical panels and controls. Efficient part design and layout prior to cutting keeps scrap and waste to a minimum. Some sample applications include:

- Thermal management labels and tapes

- Gaskets and seals

- Bonding materials for screens and circuitry components

- EMI/RFI shielding materials

- Screen and surface protection

- Anti-static material

- Rubber grip pads/”feet”

- Anti-vibration or anti-noise pads

- Adhesive strips or sheets for assembling components

- Liquid ingress protection components

- Conductive tapes

- Protective polymer films for labels

- Thermal tapes

- Heat and flame resistant tapes and padding

- Product packaging materials and information cards

Warehousing and distribution

Our warehousing and distribution services make it easy to streamline your operations and focus on other aspects of your business. MCMILLANCO can help you reclaim staff time and physical space by handling your assembly, packaging, and product preparation needs.

Assembly. Our team will assemble your components into a finished product or subassembly. Additional contract packaging and converting services are also available to help prepare your products for warehousing and distribution.

Kitting. We can pack components that are used or sold together such as specialized tapes and labels or instruction cards, gaskets and installation prep materials, or even pre-counted/pre-measured sets of fasteners or other components.

Copacking and fulfillment. We will pack your finished products or completed kits into final packaging, label them, and prepare them for shipping.

Vendor managed inventory (VMI). Using your inventory and distribution data we’ll create a plan for ordering and stocking supplies and parts. We can also use historical data and your business goals to make projections for inventory needs going forward.

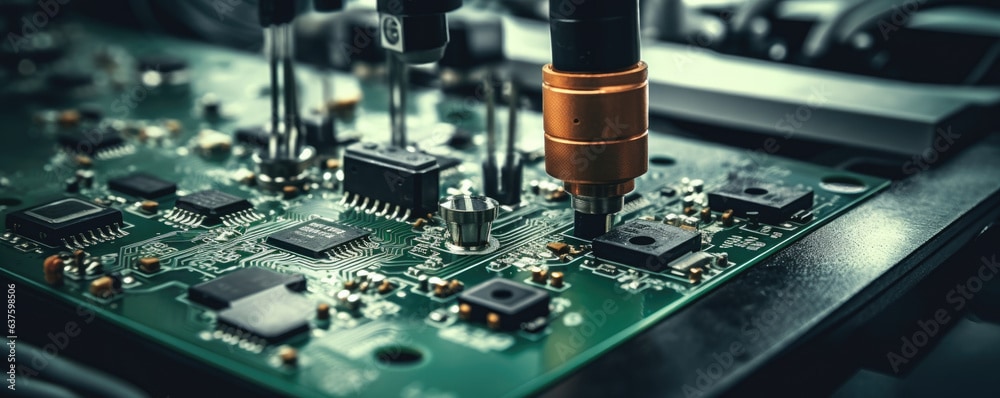

Manufacturing solutions

MCMILLANCO maintains a carefully vetted global network of manufacturing partners that can help bridge gaps in your manufacturing capabilities. As your contract manufacturer, we will connect you to the processes and finishing operations you can’t do in-house.

Or, we’ll extend your in-house capabilities for manufacturing when you need to scale production up rapidly or create small batches on a tight deadline.

Our designers and engineers bring their design for manufacturing (DFM) experience to your project for processes including:

- Progressive and fourslide stamping

- CNC laser cutting

- Welding and assembly

- O-ring and gasket manufacturing

- Injection molding

With MCMILLANCO as your contract manufacturer, you can trust that parts and components will meet your specifications and quality requirements. Some examples include electronic components for consumer and industrial appliances, vehicles, telecommunications devices, “smart” device controls and panels, and more:

- Metal stampings such as pins, clips, tabs, brackets, and plates

- EMI/RFI shielding components

- Switch and relay components

- Device housings

- Battery connectors and contacts

- Custom electronic and electrical enclosures

MCMILLANCO is based in West Liberty, Ohio, and specializes in identifying creative solutions for electronics applications through custom converting, manufacturing, logistics, and warehouse management services. Our expert designers and engineers, cutting edge equipment and facilities, and worldwide network of manufacturers are ready to help, so please contact us today.