Kiss cutting is a popular print-finishing technique used by manufacturers to produce any non-woven material that will be peeled off of any backing base like paper, foam, adhesive-backed foils, rubber, cork ,vinyl or any other non-woven media. The cut in kiss cutting technique does not go all the way through the backing material, as it only cuts through the layer that will be peeled off. There are specific instructions that need to be followed during the design-making process for the computer-guided cutter to perform the cut.

This article will help you have a basic understanding of the design guidelines for kiss cutting.

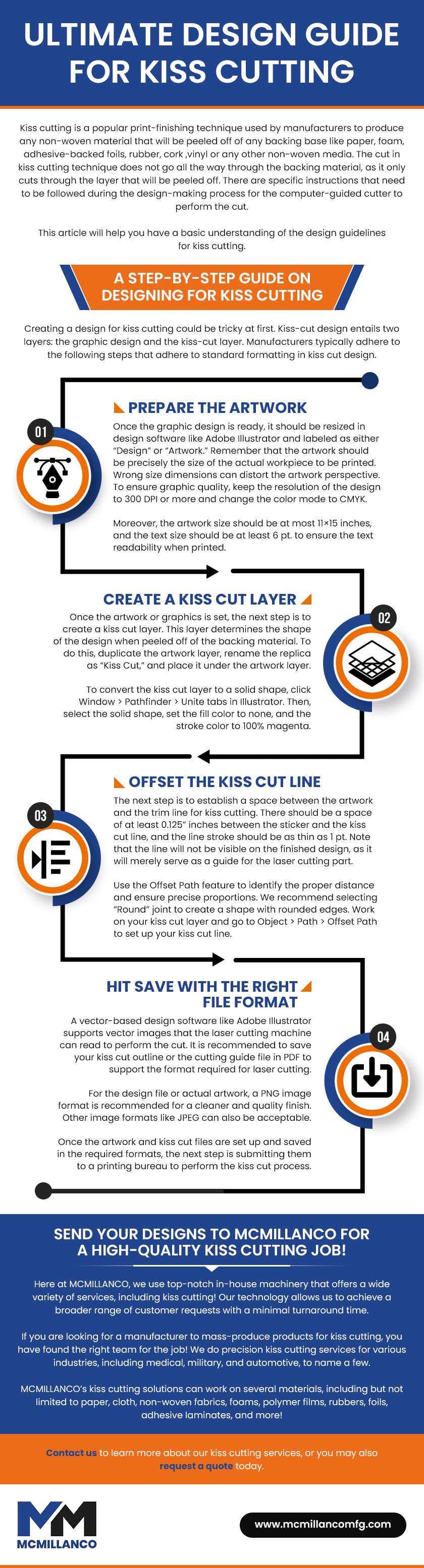

A Step-by-step Guide On Designing For Kiss Cutting

Creating a design for kiss cutting could be tricky at first. Kiss-cut design entails two layers: the graphic design and the kiss-cut layer. Manufacturers typically adhere to the following steps that adhere to standard formatting in kiss cut design.

Prepare The Artwork

Once the graphic design is ready, it should be resized in design software like Adobe Illustrator and labeled as either “Design” or “Artwork.” Remember that the artwork should be precisely the size of the actual workpiece to be printed. Wrong size dimensions can distort the artwork perspective. To ensure graphic quality, keep the resolution of the design to 300 DPI or more and change the color mode to CMYK.

Moreover, the artwork size should be at most 11×15 inches, and the text size should be at least 6 pt. to ensure the text readability when printed.

Create A Kiss Cut Layer

Once the artwork or graphics is set, the next step is to create a kiss cut layer. This layer determines the shape of the design when peeled off of the backing material. To do this, duplicate the artwork layer, rename the replica as “Kiss Cut,” and place it under the artwork layer.

To convert the kiss cut layer to a solid shape, click Window > Pathfinder > Unite tabs in Illustrator. Then, select the solid shape, set the fill color to none, and the stroke color to 100% magenta.

Offset The Kiss Cut Line

The next step is to establish a space between the artwork and the trim line for kiss cutting. There should be a space of at least 0.125” inches between the sticker and the kiss cut line, and the line stroke should be as thin as 1 pt. Note that the line will not be visible on the finished design, as it will merely serve as a guide for the laser cutting part.

Use the Offset Path feature to identify the proper distance and ensure precise proportions. We recommend selecting “Round” joint to create a shape with rounded edges. Work on your kiss cut layer and go to Object > Path > Offset Path to set up your kiss cut line.

Hit Save With The Right File Format

A vector-based design software like Adobe Illustrator supports vector images that the laser cutting machine can read to perform the cut. It is recommended to save your kiss cut outline or the cutting guide file in PDF to support the format required for laser cutting.

For the design file or actual artwork, a PNG image format is recommended for a cleaner and quality finish. Other image formats like JPEG can also be acceptable.

Once the artwork and kiss cut files are set up and saved in the required formats, the next step is submitting them to a printing bureau to perform the kiss cut process.

Send Your Designs To Mcmillanco For A High-quality Kiss Cutting Job!

Here at MCMILLANCO, we use top-notch in-house machinery that offers a wide variety of services, including kiss cutting! Our technology allows us to achieve a broader range of customer requests with a minimal turnaround time.

If you are looking for a manufacturer to mass-produce products for kiss cutting, you have found the right team for the job! We do precision kiss cutting services for various industries, including medical, military, and automotive, to name a few.

MCMILLANCO’s kiss cutting solutions can work on several materials, including but not limited to paper, cloth, non-woven fabrics, foams, polymer films, rubbers, foils, adhesive laminates, and more!

Contact us to learn more about our kiss cutting services, or you may also request a quote today.