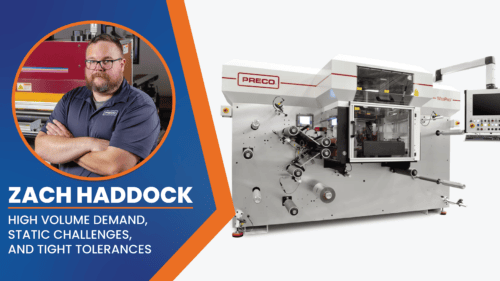

In this episode of the MFGMonkey Podcast, we tackle the complexities of high-volume demand, static challenges, and tight tolerances with industry expert Zach Haddock. As manufacturers strive to meet increasing demands while maintaining precision, understanding these critical factors becomes essential. Zach shares his insights and strategies for navigating these challenges, offering practical advice for achieving operational excellence. Whether you’re a manufacturing professional or interested in process optimization, this conversation provides valuable perspectives to enhance your production capabilities.

How to Get in Touch with Zach Haddock

If you’re interested in learning more about Preco, LLC or connecting with Zach Haddock, you can reach him via the Preco, LLC website:

- Website: Preco, LLC

- Contact Through Website: Fill out the contact form on the Preco, LLC website, and Zach or a member of his team will follow up.

- https://www.linkedin.com/in/zach-haddock/

- zhaddock@precollc.com

If you have any questions, comments, or topics you’d like to hear about in future episodes, please let us know. Subscribe today and help fabricate the future!

Contact us at:

—

Listen to the podcast here

High volume demand, Static Challenges, & Tight Tolerances with Zach Haddock

Zach Haddock, a representative from Preco, joins Dustin McMillan on MFG Monkey to discuss their experiences in the converting industry. They talk about the importance of guidance and support from Preco in helping McMillan Co. take on challenging projects and achieve exceptional results. They also discuss their shared passion for teaching and how it plays a role in their respective careers. The conversation then shifts to their shared interest in scuba diving and the excitement of exploring underwater caves. Zach shares his journey in the converting industry, starting from his background in screen printing and transitioning into applications and sales at Preco. The conversation discusses the diversity of the converting industry and the challenges and opportunities it presents. They talk about the importance of confidence in capital equipment investments and the value of being willing to take on challenging projects. They also touch on the issue of static in the converting process and the need for expertise in addressing it. The conversation then shifts to the EV industry and the role of converting in producing components for EV batteries. They discuss the high volume and complexity of die-cutting and other converting processes in the EV industry. In this conversation, Dustin McMillan and Zach Haddock discuss the capabilities and applications of die cutting machines. They explore the high-volume demands of industries like aerospace and green energy, as well as the potential for growth in the converting industry. They also delve into the topic of tight tolerances in die cutting and the different types of machines that can achieve them. The conversation concludes with a discussion on the importance of collaboration and knowledge sharing in the industry.

Zach, welcome. How are you, buddy?

I’m doing well. How are you, Dustin?

I’m doing awesome. I appreciate you jumping on to MFG Monkey and chatting with me today.

Yes, I am super excited. And I appreciate you reaching out and asking me if I’d come on.

Absolutely. We hit it off once we were introduced. Probably it was a year and a half ago now, maybe longer.

I think I was out of your facility, probably a year and a half ago, probably about that.

We have always leaned on you guys quite a bit getting up and running with the machine that we bought from you. PRECO has always been just phenomenal to work with because it is new to us. We jumped into the converting industry with both feet and never looked back. Your guidance has been exceptional for us.

I appreciate that. That’s kind of a byproduct of enjoying what you do. And that’s not just me speaking about myself personally here at PRECO, but just everybody here. We are very passionate about our business.

Yes. I think Steve was the one that came out to help us get our machine set up. We had him out a couple of times, I believe. His willingness to help and just laid back and how he teaches, and things like that. And then anyone inside PRECO, if you’re not available, anyone’s more than willing to help us and answer questions and help us understand what we don’t know.

That’s kind of one of the things that we are very proud of. We have nearly 50 years of collective converting experience and a lot of tribal knowledge built in. When you do business with us, we share all that, we’re not converters, we’re just making the equipment. We want our converters to go out and be successful.

Definitely. You have helped us a lot. We take on very challenging products. I think it is mainly because we want to separate ourselves from the industry. The machine that we bought from you is extremely capable. We can take those projects confidently, but a lot of times we’ll get ourselves into something unusual. I know this thing can be done, but I don’t know how.

Well, I remember the first time we met face to face. I remember you saying that we are going to go after the jobs that nobody else wants to tackle. And that’s huge. There’s a lot out there in that arena.

Yes. And there is this one project that I can think of that you helped us out tremendously with was the military project. It seemingly was simple, but we were holding to such a high tolerance with a target, and you helped us get that lined out. It took us a little bit to get the machine lined up a lot because the media coming in wasn’t consistent. There were some issues there, but we ended up just crushing that project. We ran close to a million pieces. We took our customers’ scrap level from what they were doing previously to over 70%. And I think we delivered well under a 3% scrap rate.

That’s fantastic. That’s huge, right?

Absolutely. It saved them hundreds of thousands of dollars. And a lot of it. Well, it was the machine, the digital locator, you helped us understand where that target needed to be located and how to get the machine set up. There is a lot of learning on our end because we have never done it before. But our team just knocked it out of the park. I think you were on FaceTime with Diego quite a few times to help, so thank you for that.

Yes, no problem. I always make a joke about it about how I’m never off the clock, but I am not. My wife doesn’t think the jokes are as funny as I do.

No, well, when you’re in sales or when you run your own deal, it kind of never ends and it takes that passion to be successful. You have that with all the videos that you have and things like that, teaching is the best sales tool, I believe.

I would 100% agree with you. And it’s kind of hard for me sometimes to call myself a sales guy because I’ve only been on that side of it for my career for relatively a short time in the grand scheme of things. But I’ve kind of always come from a teaching background. I grew up both my parents were teachers and coaches and I’ve always coached and taught. That part of it to me has always been kind of second nature and I enjoy it a lot. I hope it helped me become a good salesperson, but that’s precisely the side I lean on hardest of being a teacher and sharing, right?

For sure. Yes. When you take that approach, the old school days of the ABCs. Those days are gone. It’s all about teaching and relationships. Doing Podcasts. I want our time together today to leave an impression on somebody to help them understand something that they didn’t know. Same with me, I’m going to learn a dozen things while we’re chatting.

Well, I hope so, but no guarantees.

Understood, understood. Even when you’re talking about coaching and teaching and all that. That’s one thing I learned about you last week, you’re a dive instructor too.

Yes, I tend to go all in on things when I get passionate about them. It’s kind of interesting. I had always wanted to dive my entire life and like all things, found excuses not to do it. About eight or nine years ago, I was sitting there thinking, there are no guarantees that I’m going to be able to do this physically, mentally, and financially at the time. I was planning on going to get in the surf, but I am not sure. And decided I’m just going to go do it. And so, I enrolled in a basic open-water dive class and dove for a couple of years just as a basic open-water diver, had a blast. And then my oldest son at that time turned 10, which is the minimum age you become a certified diver. I went to the shop that I was diving through, and I talked to the owner, and I said, hey, my son wants to get certified. Will you certify him? And he sat there, and he thought about it for a second and he goes, I will. But if I certify him, you’ve got to get certified as a rescue diver because you can rescue him, but he can’t rescue you. That made total sense, right? It’s an incredibly safe sport, but it’s like everything that there are some inherent dangers. So, I went on and I got my advanced then I got my rescue, and on the end of the first day of the rescue course, which once you take rescue, that’s kind of the last thing you can do before you got to make the decision. I’m done or I’m going to become a professional. They ask who’s interested in becoming a dive master. My hand shot right up as I knew instantly. I want to work with people. And it’s easy to get excited and to share things when you’re passionate about it. Fast forward, nine years later, I’m now a master scuba diver trainer with Patty. And then I also got into the tech side. So, I do cave diving, rebreather, deep trimix, and all that other stuff. So full bore down the rabbit hole.

Wow. That’s awesome. And I’m where you were 10 years ago, I guess I’ve wanted to dive for several years. And I spent a lot of time on a boat. And I was thinking about it when we were in Florida last week. It would be a lot of fun to be out in the water right now instead of sitting on the beach or just fishing or being on a boat at night.

Yes. Just knowing that you like to fish. That was one of the big draws to me as well because I’d always liked fishing and fly fishing and just any kind of fishing. I don’t know how to describe it. But when you’re snorkeling or you’re wading, the fish know you’re not supposed to be there, so they’re just gone. But the moment you drop below the surface, you’re just part of their world, they’re just right up on you. It’s so cool.

All right. I guess I lost my internet connection there for a minute.

Yes, no worries.

Hopefully, we’re good. It’s still recording, and we’ll do our thing on the back end. I think was saying something about Barracudas when my connection got lost.

Yes, Barracudas. They have some teeth on them.

Yes. And they’re not afraid of you.

No.

There was a video that I was watching of a lady getting ready to dive and she’s sitting on the platform, and she sticks her face in the water and clears her mask. Suddenly, she comes back up and a shark is right in her face. Have you seen that video?

I don’t think so.

The shark is right in her face, and she is nonchalant. Grabs the nose and pushes it under the water and then she gets in. I probably would have skipped that day.

You know, it’s weird. I’ve dove with sharks and dove with tons of Barracuda. With Barracuda, I always have an eye on them to want to know where they’re at because they’re not afraid of you. They come cruising right up to you. I’ve never felt the heebie-jeebies from sharks at all. I’ve had them buzz by up close, but oddly enough, the thing that just makes my skin crawl underwater is eels.

Yes.

When their mouth is going open like that, it just kind of gives me the creeps. In December, we were in Bonaire in the Dutch Caribbean, and my buddy I was diving with said, hey, look over there. I look and there’s this big butter, gosh I’m blanking out on the name. Parrotfish. Look at that huge parrotfish.

Yes. Okay.

So, I got real close and I got my GoPro and I’m getting real close on it. And I kind of look out the corner, my buddy is shaking his head. He goes, which is the sign for an eel. And I looked down and it was right under my chin. It’s like, yeah.

Oh, yes, I saw a video yesterday of a guy petting a moray, is it the moray eel, they are huge green. So, it was like he was petting it like a dog. And I’m like, oh, yeah. I was waiting for the thing to like to eat them.

Yeah. I think I saw that same video, he’s like cuddling with it. Yeah. No. They’ve got some big old nasty teeth on them.

Yeah. But yeah, I can’t wait to do it. I think I’ll have a lot of fun with it and be a cool activity. And there are places I boat a lot up at Erie and there are some wrecks that you can dive on. Which I think would be super cool. Cold, but you probably dive in a lot of cold, cold water.

Yeah.

I do. You know people, my students especially, will ask where I like to dive. And I kind of half-jokingly, but half seriously say anywhere wet, right? But being that I’m in the Midwest, you know, I’m based out of Kansas City. If I want to dive year-round, I pretty much have to be able to dive in all water temperatures. So, I think the coldest I’ve ever been in is like 40-degree water which is dry suit weather.

Yeah, for sure. Where’s your favorite place that you’ve ever dove?

So, for ocean diving or open water, Bon Air is high on the list. I don’t know how familiar you are with it, but basically, that is pretty much all that Island exists for its production of salt and scuba diving.

Okay.

And there’s something like 80 dive sites there and it’s all shore entry. They call it the home of diving freedom because literally if you want to get up at three in the morning, grab some tanks, and go up in the water, nobody’s going to stop you.

Wow.

And it’s just incredibly beautiful. You know, turquoise blue, clear water. You can see the bottom 150 feet below you. I mean, just crazy and tons of coral, everything. On the tech side of it, I do enjoy going into caves. And people joke around about that and say, well, you know, all you’re seeing is what rocks, which is true. But for me, what’s enjoyable about it is the whole process because it’s probably the closest you can get to going into outer space, right?

Right.

You’re going in there. If something happens, you must have everything. The training, the equipment to get you back out. But the flip side of that is, you’re going into places that when you look at the global population like extremely small percentage of humans ever get to put their eyes on. And I get excited about the fact that I’m seeing things that just not very many people get to see.

Sure. Yeah, I don’t know. I don’t think I’m a big claustrophobic person, but I don’t know how I would feel in a space like that. It would take me a bit, I think.

Yeah, I get that. I get that a lot. And I always tell people you don’t have to put yourself in that situation unless you want to. A lot of the caves we dive in, you can almost literally drive a truck through. They’re huge.

Oh, wow. Okay. I got you. I was envisioning it like a tight little wormhole. Yeah.

Well, you can do that too, but that’s not if you don’t want to.

Sure, sure. No, that’s super cool. But I was just surprised that I’ve known you this long and didn’t know. I mean, that’s a pretty big piece of your life. So, I’ve found that super interesting.

Well, I don’t physically fit the mold of what people think of as a scuba diver either.

Well, I mean, do we? Yeah.

Six foot four and three hundred pounds.

Yeah. You’re a big boy. That’s for sure. Very cool. So, I guess I’ll jump back to the business piece of this a little bit more. But give us a little bit of background on how you got into the converting industry. You’ve been with PRECO for a long time, maybe you’re on more of the tech and troubleshooting for the majority of your time. Right.

Yeah, it’s a great question that you asked that. And that’s one I ask people a lot too, because in the converting world, everybody’s got a story of how they got here, right?

Yeah.

Because no kid when they were in first grade during career day, raised their hand and said, I want to be a die cutter.

Right. Yeah.

You know, it just doesn’t happen. And so, I kind of fell into it as most people do. How I ended up here at PRECO, my background, I got my degree in commercial graphics with an emphasis in screen printing. And so specifically functional screen printing. Printing circuits, printing solar cells, EL displays, and things like that. And PRECO at the time, when I came here, they were building roll-to-roll vision registered screen printers to do just that. And we were using our vision technology that we use on all our equipment to register very, very precisely that ink passes. And I’d been out of college for maybe four or five years. And I saw this job posting. And I’d been out of college, for four or five years just basically working at a printed apparel screen printing shop. Not at all what I wanted to do. As a college kid, didn’t really think very far ahead of what I was going to do with the screen printing and I’m going into something that’s really pretty niche on the functional screen-printing side. But anyway, I saw this ad for PRECO, and it was pretty much exactly what my formal education had trained for.

Sure.

So, I’m going to go apply for that. And ended up getting the job and worked here for about a year doing applications, and technical work on our screenprint stuff. So specking out our equipment, doing installations, training, process design, things like that. About a year after I started here, PRECO had decided to start developing our rotary die-cutters. And they came to me, and they said, do you want to not only do the applications work on the screenprint side, but are you interested in doing applications work on the rotary as well? I’m not very good professionally at saying no when people ask me to do things. It could be a fault or a positive one way or the other, but so I said yes, I’ll do it, but I have zero experience. I don’t even know what rotary die-cutting is. No problem, learn on the fly. So, I did that for about seven years doing applications on rotary die cutting.

Same capacity as screen printing, you know, specking out systems, doing process development for people, training installations. And then our flatbed equipment, the guy that was doing applications on it, who had been doing it for 30 some years, his name was Randy Norman, and very well known in the converting industry for what he, his knowledge and just being able to figure out problems when it comes to converting. He decided he was going to retire in four or five years. And so, he kind of took me under his wing. I started doing application work for all three at that point. And I did that for about 14 years, just working on the tech side. I was out of our engineering group doing a little bit of design work, mostly processing stuff, training, and doing some consulting work for customers. And then in 2021, there was an opportunity that opened up to step into a sales role, and I was approached by our sales director of sales at that point. And he asked me if I wanted to step over into sales. Again, not great at saying no professionally. Was nervous as hell.

Right.

But I knew that I knew all of our equipment inside and out. So, I decided to take that step and then realize what real work is.

Yeah.

You know, I joke around with all our other sales guys here. And I said, you know, I used to walk by your guy’s office, and I’d see you staring at your computer all day. I thought you guys were just screwing off on the internet. I had no idea you were really working.

Ha ha ha.

But, I’ve loved every minute of it. It’s been the best career move I’ve ever made in my life. And I think I finally found where I can settle in and I get the opportunity to continue to help people and coach people and now I have a lot more freedom in it than I did before, right? So, I really, really enjoy that side.

Yeah.

But yeah, all total I have been here about 17 years. I think I’m starting my 17th year this July.

Oh, wow. That’s awesome. Yeah. Congrats on that.

Institutionalized. I don’t think I can go to any other industry now.

No, no, you’re stuck. I don’t think they’re letting you leave at this point.

Yeah, well there’s probably days that I wish I would.

There are days that people wish I would quit too. So, I think they’re stuck with me though.

They don’t have a choice.

Right. Yeah. I had a similar experience before. We had our little blip there. We were talking about getting into converting by accident and MCMILLANCO totally got into converting by accident. We were helping a company develop a product and we found a company that could do all processes except for the sheeting piece that we needed to do for them.

And Connor ran across you guys. And I believe the machine that we ended up purchasing was a 3M machine that you sold to 3M for a project. And then that project died. So, they sold it back to you. Connor came into my office, and he was like, hey, I found this machine that can do everything. I don’t know that I want to buy a machine to run one product, you know, this one customer on. But we looked at the numbers and it made sense, long story short, we ended up buying the machine and I didn’t even know what converting was when we bought the machine. And we’ve had it now for four years, I think. And it was, you know, we got it in. Steve came out and helped us get it set up and we were running product, you know, that same day. And unfortunately, the customer that we bought the machine for went out of business within a year. But we just made the decision just to keep it and, you know, figure it out. And so far, it works. It’s been challenging, especially not, you know, never being in the industry before it’s not like I had a deep network of customers that needed converting work. So, it’s been especially on the sales end of things for me, it’s been a rewarding challenge to take something that, you know I didn’t know anything about and build a business out of it.

Yeah, you know, and I am just talking about MCMILLANCO. When you guys purchased that system, I always do a little bit of just kind of web search and try to learn a little bit about the company. And I was just floored, especially the first time they came out to your facility at how diverse you guys are, which is awesome. And it seems like everything you do, you do very well. On the converting side, one of the feathers in that cap is that most people don’t realize how diverse the converting industry is.

Yeah.

And when I say that, I mean, just turn your head 360 and look around your room. I can go around and just start picking up parts and say, this has got a die cut part, this has got a die cut part, that’s got a die cut part. And literally, everything around us from, you know, the little CR 80 coupons you get in the mail all the way to components floating on the satellites above us all have something in it that a converter made.

Right.

Just everything.

And that was a learning curve for me because I had no idea. Now I could walk into a factory, and I could pick out all the machine parts, all the four slide stamping parts, all the springs, the castings, what kind of casting it is. Look at the casting and tell if there is a problem with it. So that was something that you know, just for my own tribal knowledge that I learned over the years. And then I got into this converting thing, and I knew nothing about it. I’m still learning every single day. You know what pieces and what parts we can make, and we can’t make. And a lot of it is just having the confidence that I know when we made the foil that copper foil product, a lot of people told us that is just not possible. You can’t cut, you know, you can’t kiss cut something that’s formal thick. And Scott at the time, was like, we can do that all day long. I’m like, okay, I must be confident that we can do it. I think Connor and Brandon flew out and spent a couple of days with you guys and any trained him and we sent the product out there and he helped them run it on, on our machine now and you know, Connor calls me, he’s like, it can do everything we need it to do, which was a huge confidence builder, not knowing what we were getting into, that you guys had the whole machine set up at your facility and taught and showed us that it would work and it’s like, okay, well, let’s roll with it then.

Yeah, you know, a capital equipment investment is nothing to turn a shoulder to, right?

Yeah.

So, you have to make sure that you’re confident in it and that it’s going to work for you. Yeah, absolutely.

Yeah. I mean, some companies, you know, what we spent on that machine, it probably isn’t a big deal to them. But for us, especially at that time, it was a monster investment. I mean, I had never bought anything that expensive in my life except for a home. And it was a leap of faith that we would make it work.

Yeah.

But again, without you guys, I don’t think we would have been able to if we would have bought the machine from, you know, China or something. We would have never made it work.

Yeah, well, you know, we’ve been building the system you bought, which was a flatbed die cutter. We built flatbeds, rotaries, and lasers. We’ve been building flatbeds since 1976.

Yeah.

And now that I’m on the sales side, I realized that I wish they wouldn’t have been built so well because they don’t ever, they don’t ever fade out.

Ha ha ha!

They are a pretty big investment, when you get a good job on them, they only cost money till you turn them on and then they start producing it.

Yeah. And that’s the thing for us. I mean, we paid for it with one job, which was huge. There are not a lot of machines that you can say, okay, we have less than a year ROI, let alone a month or two. I know guys that are buying machinery that it takes them five years to pay the thing off and that scares the hell out of me.

I think it ties in a little bit, or it is a credit to MCMILLANCO. Kind of going back to what you told me about we’re going to go after the stuff nobody else wants. That’s a huge value add, right?

Yeah.

When you’re willing to be the person to step up and say, yeah, I’m going to do it, that gives you a pretty good leverage point and lets you really attack things.

Yeah. And we’ve won business and what gives us that confidence is coming to you and saying, hey, we have an opportunity to do this. Is the machine capable of doing it? And you guys go, yep. And I go back and have a hundred percent confidence. Yes, we can do this. We can hold the tolerance, we can hit the rate, we can do whatever they’re asking. And what we’ve done a couple of times is we’ve had customers say, hey, we’ve been trying to make this part for three years. We cannot hold tolerance. We haven’t found anyone that can hold tolerance. You’re saying that we can, we don’t want to invest in the tooling. You know, what if you can’t do it? And that’s a really easy conversation for me. I say, okay, well, I’ll buy the tooling, we’ll prove that we can make it. And once you approve, you know, the first article, then you pay for the tooling. If we can’t ever hit the dimensional requirements, then. You know, I eat the tooling.

And I mean, for a customer that just, I mean, why would they say no to that? We have done that a few times and it worked out well. And we have had challenges. I mean, one part was like this little foam disc that we were making. And I never thought that the static involved in it and we had these, you know, millions of pieces stuck all over the damn machine and we’re calling you for help trying to figure out how to get the static out and how to get the parts in the box and not everywhere. But that’s the fun part too. And it’s rewarding for our team because they have a huge sense of accomplishment once they get it figured out, once it’s running well and things like that.

Yeah, for sure. If you don’t mind me asking, what are some of the tolerances that you find you’re being asked to hold these days?

Um, the one project was the military card. And if I remember it was like in the machining world, it’s wide open, right? I think it was plus or minus 30 thousand and we could hit that all day long. And it took us a little bit to get to the target. It took us a little bit to get the material to feed through, but that was mainly a material issue because there wasn’t enough material on the backside of the machine. There’s plenty of material on the front side of the machine, but on the backside, they cut it pretty close like the bleed line and we were getting some issues with the material walking. But once we got that figured out, we just stopped running the material that was bad. Our scrap rate was phenomenal. We made a little go-no-go gauge because we were trying to measure everything, and we just made this little 3D-printed go-no-go gauge where our folks could put the piece in there. They closed it and if it was good, it was good. If it was bad, it was bad. And we didn’t have any parts rejected. Yeah.

That is awesome. Yeah, I like to talk to her when I’m talking to people a lot, you know, kind of in similar situations like that where maybe they’re not doing the entire process in-house, maybe somebody else is printing it and then it comes to them and they’re just converting it and it goes down the line. You must keep all of those lines of communication open, right, from one end of the line to the other.

Yep.

I always like to kind of joke around and say it’s kind of like the framing carpenter comes in and frames it and says, well, now it’s the drywall guy’s problem. And then the drywall guy comes in and he says, well, now it’s the trim guy’s problem.

Yeah. Exactly.

And you got to keep that open front to back because the guy that’s doing the printing may not fully understand what you’re going to need on your end, and you may not fully understand what the next step down the line is going to need. It just makes things move so much smoother, right?

Yeah. Well, that was a learning curve for us, especially on that project. When we received all the material, it was wound backward. It was on the wrong size core. We had all those notes on the drawing, but for whatever reason, it was missed. So, that was a learning curve between us and the printer, not having enough material on the backside that was something that we understood with the customer, but that it wasn’t clear on the drawing, so we modified some notes and things that we learned and it, there’s some tribal knowledge there and the printer was awesome. I mean they took responsibility for what they needed to take responsibility for, and we were able to get it rewound on the right size core. And the next time we get the material, it’ll be printed properly. And I’m sure our scrap rate will go down even more. I just pulled up another drawing because I knew, I thought that there was something that little foam disc was, the center hole was plus or minus 20 thousand. So, it was even tighter, and we could hit that so well that they changed the tolerance because they didn’t expect that we would be able to hold that. And we were so dead nuts about that. They’re like, okay, we have to change the tolerance because you can hold it so well.

That’s awesome.

Yeah. And kudos to the die maker, and engineering for figuring that out and holding those tolerances.

Well, and you know what, the fact too, you kind of just solidified that they can’t go anywhere else because they’re going to go with their new drawing. They’re like, we can’t do that. They’ll come right back. Yeah.

Yeah, absolutely. The same thing with the military project that we’re doing, with the amount that we saved them. I get to their facility, and they have these red tubs sitting everywhere. And I’m like, oh, red tubs are never, never good. It was hundreds of thousands of pieces in these red tubs. And I’m like, is this all-quarantine stuff? And they’re like all of it’s out of tolerance.

I’m like, wow, hopefully I didn’t bite off something we can’t do. So that made me a little nervous going in there. I hand delivered the first articles to them because we got material like, six months later than what we should have. And, you know, all those things, thank goodness that wasn’t on our end, our responsibility. But yeah, it’s fun when you can do jobs like that.

So, on the static on those foam parts, what did you all end up doing to combat the static?

We ended up grounding something with copper wire. It’s been three years ago, I can’t remember exactly what we did, but I believe that we ended up grounding the press section and I believe, I think it was just the press section, maybe the rollers. I think there was some static being caused there, so we had to ground the feed roller and the press and maybe something else.

I was just curious because static is always, I don’t want to say always, but man, when it rears its ugly head, it is a real booger to deal with.

Yeah.

And a lot of times, I’ll try to help and advise where I can.

Yeah.

But what I see static-wise here in Kansas City in July in our climate control building, I could have it running perfectly here, but the moment I send it to customer X out in Arizona in the desert in December

Yeah.

Everything I did just went out the window.

Oh, a hundred percent. Yeah.

And it’s like you really have to address those issues right there. And I always recommend people bring out a static expert. To me, static is kind of like voodoo.

Yeah.

You just start trying to figure it out, dump some chicken blood over it, and throw some bones on a plate. That’s not true. But there’s a higher level of understanding there than what I have. So, I always recommend that you try to, if you have static issues, you really need to, if they’re bad, I mean, there are easy ones you can address, but if you have bad static issues with materials, to bring in a static expert and address it right there at the point.

Yeah. And I think that’s what we’ll have to do next time because I don’t even know if we one hundred percent got it figured out. Then it was a new product that this medical company was making, and it ended up not taking off. So, I think we got it figured out well enough to deliver. But we weren’t running big production where we had to go down that path, but we probably would have had to bring in an expert. Just because we didn’t get rid of it a hundred percent.

Yeah, and sometimes you can’t.

I remember years back, this was when we were still doing the screen printers. We built a system that was making RFID tags, actually I believe it was for the tickets for the Beijing Olympics. And part of the process was this PET material got dragged across a cooling plate. We got plastic dragging across this metal plate.

However, many hundreds of times per hour and then rewinding onto this roll. And it was a clear roll with circuits printed on it, but you can stand at the back and you can see little lightning bolts running through it.

Oh, wow.

And just like, oh my God, that thing has such a huge charge built on it. And yeah, then also kind of getting a giggle when you’d see somebody else in the shop walking by and they go over and they start to put their hand on it. Oh, you’re about to get a good zap. Yeah, yeah.

Yeah, zap. Wow. Yeah, I don’t think we have had any lightning bolts.

But yeah, static. Yeah. Yeah, well, kind of going back to my days before pre-PRECO, when I was in the apparel company, they did a lot of cutting. So, they would pull polyester back and forth on these cut tables and they had a metal rail, right about thigh-high on it. And man, that would build such a big charge and you walk by, and it’s zap you.

Yeah, that’s the static. It did blow my mind because I didn’t think about static being an issue. And I walk out and there’s just these little, you know, they’re that big. Point half an inch in diameter and they’re just stuck everywhere. And I’m like, what is going on here? Guys had them stuck all over their arms.

Well, you know…

Yeah. And you know, you, you’re running it in December. You’ve got terrible static issues and you come back in July when it’s hot and humid and suddenly it runs fine. It’s just, it’s so temperamental.

Yeah. It is so interesting how the material reacts to temperature change or humidity or barometric pressure. Years and years and years ago, I worked for a company that did deep-draw metal forming, and we were doing different military projects. This one project that we were doing, was a cylinder that was approximately four feet in diameter at different wall thicknesses throughout. It was a very difficult part to make. And when we were deep drawing it, we were turning the thing inside out and we had to anneal it and do all these things. In the winter, we would have to set the standard deviation of the tolerances differently than we would in the summer because, even though it measured appropriately in our shop, when it got to the customer, by the time it traveled on a truck in the cold. It would shrink and it would be out of tolerance. And it was our metal or just at the time, we’re like, what is going on? But the tolerances were so tight that it just changed everything. So, you would have to make the thing out of tolerance and ship it. And then it would be in-tolerance by the time it got to the final facility.

Yeah, that’s really cool. Yeah, you know, kind of a similar story that we had a project years back where we were cutting, you remember when the 50 state coins came out and they had different quarters for every state. We were cutting these we had a customer that was cutting these cards that you could put all the coins in. And it was probably about an eighth to three-sixteenths inch thick, foam core with a bonded layer on the outside that had printing on it. And all we were doing was cutting the holes for the quarters. What they found out was when they shipped them by air, and you got in that low-pressure environment, that the material expanded because it was a closed cell and it expanded so much that it made all the ink pop off. And it was crazy. So, they had to switch the foam. And there for a while, I had to have a caveat on it that you can’t ship it by air. Just really interesting.

Yeah. Interesting. Yeah. We’re working on a project. It’s a new product that this guy is developing in the fishing industry. And we were trying to do something that we certainly haven’t done before. And it’s a die cut on the perimeter. And then we’re kiss cutting within the die cut only, you know, we’re trying to go halfway through the foam and we’re running into issues where some of the cuts will be deeper than the other parts, you know, the other cuts. Just because of the nature of the material is just, you know, splits differently, I guess. So, we’re evaluating different types of foams and all kinds of things. And the die maker, they were running a test on a clicker press. So, I’m hoping that when we get it in, we have much, much more control of the depth. So hopefully that’ll solve a lot of a lot of problems. But it’s challenging. That’s a challenging part that we’re doing right now.

Yeah, interesting.

Yeah. And it is, I, you know, I’m a big fisherman, so I kind of took that on personally to try and figure out. That project we’re not going to make money on for a long time.

But are you going to be doing product testing?

Yeah. We will. So, it’ll be fun and rewarding once we do figure it out and that, so.

Yeah, that’s super cool. Yeah, we’ve had a couple of projects in the outdoor world, kind of fishing. I know we had one, it was a foam fishing lure, but the idea on the foam was is that it got, the fish’s teeth would get tangled in it so that they could, even if you didn’t get a hook set, you still had a good chance of landing it. It was pretty awesome.

Right. Was that for a gar or what kind of fish was it?

Yeah, I’m not sure what species they were exactly targeting. Right, it’s not going to work for like bass or crappie or anything like that.

Right.

But it was interesting. We’re just cutting the shapes, you know, the shad and the worms and things like that.

Huh? That is interesting. I wonder if it was for a gar because we would fish for gar with pantyhose, a white pantyhose. And that was it. There’s no hook, no nothing. And we’d fly fish for them, and they would hit that pantyhose and their teeth would get tangled in the pantyhose. And that’s how we caught them. Yeah.

Yeah.

That’s awesome. That’s a whole other fight on a fly around too.

Yeah. Those things are freshwater Barracuda. I mean, they’re wild. But, what do you see in the converting world in the EV industry? The EV industry is the big hot topic buzzword.

Yep.

You know, Ohio, in manufacturing, Ohio is one of the you know, the biggest manufacturing arms in the US.

Yeah, yeah. Yeah.

There’s a lot of push for the EV and PCB boards, aerospace. I mean, those are the three big industries that we’re being pushed towards especially. What are you guys seeing on your end?

Yeah. So, specifically that industry is one that I’ve been targeting, working a lot in EV batteries hydrogen fuel cells, and hydrogen electrolyzers. It is very fast-moving. Everybody has their own design. There’s no standardization in it, right? So, you’ve got the big three automakers that are working on their own pack designs. You’ve got independent companies working on pack designs. From the converting side of it, what a lot of people are starting to learn, what I’m pushing people for is to learn how these packs are made. There is a boatload of components, even in a single prismatic cell that have to be die-cut.

Mm-hmm.

You’ve got the electrodes, both cathodes and anodes. You’ve got separator layers, you’ve got thermal management, so chimeric and things like aerogels for thermal runaway, then you’ve got all the gasketing inside of it too.

Mm-hmm.

There’s a ton and there are so many people doing it, there’s a lot of opportunity there. Kind of a lot not laughably, but the part that I’m trying to think of the best way to describe it. I don’t want to call it the gotchie, but the one thing that I advise people to kind of be aware of too is a lot of these companies that are coming up with these designs are rushing into manufacturing before the designs are complete. So, you can imagine on the converting side, you’re trying to tool up and get set to make this stuff and you’ve got an ever-evolving, changing product that you’re trying to tool up for.

Sure.

So, you know, I always advise people to really kind of be aware of that, that’s probably going to happen. But the sheer volume in those components that need to be produced, I mean, if you take a prismatic cell or prismatic battery, there can be up to 52 monocles inside of it. And of those 52 monocles, you’ve got three components in each monocle that potentially could be die-cut.

Right.

So, what’s that put you to? 106 die-cut parts per prismatic pack. And there could be, in an EV, you could have a hundred or more of those prismatic packs in there. So, you start extrapolating those numbers out and that is a lot of parts that need to be die-cut. And that’s what everybody’s rushing to now is how can we produce these parts at a rate that will keep up with the projected demands?

Mm-hmm.

And I don’t think personally, I don’t think any of the OEMs are going to get there on their own without investing mega dollars into doing these gigawatt factories and things like that. They’re going to have to look to outside converters to help support.

Yeah. We were, I mean, we’re excited about it. We’ve had a few companies contact us that are overseas that want to make batteries here and they sent us presentations of what needs to be cut in the layers. We’re able to laminate, you know, five or seven layers on the front end, which is something unique that you guys have told us that we’re set up that not many people are to laminate and run right into the press section. So, we’re able to do that the only part that we’re not able to do that I saw is the wet coating on the front end.

Yeah.

So that’s something that we would have to figure out. I don’t know if we can do that in line or not. Or if we have to laminate everything and then set up a separate operation to do the wet coating or how that would work yet.

Yeah, you can add wet coating in line. It’s definitely doable. And that’s the other aspect of it too, it’s not really just the die-cutting on the converters, like you said, the lamination of those, the slot coating. I don’t know any specifics about that product, but a lot of electrodes will take either copper or aluminum foil, usually around four thousandths thick. Then slot coat the “soup”, the electrode material onto it and place that on it.

Mm-hmm.

Fundamentally, the converting side of these components for battery and the EV, nothing too complex.

Mm-hmm.

They generally want higher tolerance though. And really the biggest challenge in it is just the sheer volume. They’re looking for enormous, enormous volumes in a short order.

Yeah, we quoted a project, it was an ag project. And the volumes were a hundred million up to 200 million. And with our rate, I want to say we could, we could keep up with that pretty easily. We would have to run three shifts to make sure that we had enough capacity for everything else. But I think we could deliver what their monthly needs were by running a week at a time.

Yeah.

We have to set up a run for a week and ship and do that each month. But I was really surprised when they told me the volumes, I’m like, oh, is this possible? And then we started running the numbers and we could easily keep up with it. So, I was pretty impressed with that.

Yeah. You know, in that, what I’ll call the green energy move, for converters too, that I don’t think a lot of people are looking at, but they should, is the hydrogen industry, both the hydrogen fuel cell and the electrolyser.

Right.

For all intents and purposes, they are really kind of the same device, just one takes hydrogen and turns it into water and electricity. The other one takes water and electricity and turns it into hydrogen.

Right.

But at the component level on those, typically what we see is that the tolerances are a little bit more relaxed than what you find in the battery market. And the volumes are more manageable. But the price you can command on these parts is a lot higher.

Yeah.

So, on the converting side, tends to be a little bit lower-hanging fruit. And that is a market we see growing quite a bit as well.

Interesting. When you talk about tight tolerances in the converting industry, let’s talk about that a little bit because tight tolerances are. You know, you’re in aerospace machining. We could be talking about microns, which is a whole hell of a lot different than tight tolerance in the converting industry. What kind of tolerances are you guys able to hit? Either rotary or flatbed.

Yeah, so I’ll dress a little bit more globally and then I can break out the different systems because if you look at rotary and laser and flatbed and you were to draw them up in a Venn diagram, there’s a lot of overlap. There are a lot of things they can all do, but there are absolutely sections where they shine over the other. In general, what we would consider to be a tight tolerance would be something in the plus or minus, like an extremely tight tolerance for converting would be something in the plus or minus one or two-thousandths of an inch dimensional tolerance. If we were looking at cuts to features like registration, we’re capable of going down to the micron level on a system if we had to. Granted, that’s a custom system, not off the shelf, but we’ve done it, and it can be done.

Mm-hmm.

Typically, what we see, what I would say is the lion’s share of tight tolerance jobs is in that plus or minus five-thousandths of an inch. Now, when we look at it, if we want to look at it as a kind of rotary versus flatbed versus laser. Laser and flatbed are going to be the most accurate simply because they operate in a step and repeat function. Whereas the material is stationary when we cut it. And the die is coming down and it’s completely plunging through the material at the same time. So really the tolerance, I don’t want to say completely but largely is tied into the die at that point. Not completely because we do have to control the material tension and things like that. You know, using the analogy, if you cut a rubber band and the rubber is under tension, it’s a circle when you cut it, but the moment it releases from that tension, it becomes an oval.

Right and has memory.

On the rotary side, it’s very accurate. We can hold on to the high accuracy side, we can get to that plus or minus 5,000ths of an inch, five to 10 is what we’d call the high accuracy, 5,000ths to 10,000ths inch. The reason it can’t hold quite as well as a laser or flatbed is that it’s operating on continuous motion. So, it’s based on the principle that you’ve got this material going by and you got the die rolling over the top of it.

Right.

Those dies are machine to incredible tolerances, you know, half a thousand of an inch plus or minus, but the problem is that material is moving even a fraction faster or slower which affects your down web dimension on the part. And you’re never ever going to be able to guarantee that the die is truly turning at a one-to-one ratio with the material. So, you’re always going to have a little bit more variance there. And then, you know, on tolerancing too, and it is something I know you’re wholly aware of as a converter, material plays a huge part in the tolerance as well, right?

Yeah, absolutely.

We will have people that show up and say, hey, I’ve got this 16th-inch thick ultra low-density open cell foam. We want to hold plus or minus five thousandths on it. I mean I can cut that tight but not with that material. You know it’s just not going to happen.

Right. Yeah. And the depth that really blew me away for the kiss-cutting purposes, the depth that we can hold. It was astonishing to me that we’re able to hold, you know, fractions of 100 thousand, which is kudos to you guys, I think that PRECO is the only machine maker that can do that if I’m not mistaken.

I won’t say we’re the only people out there that can kiss cut. I will say we’re the only people out there who can kiss cut to the resolution we can. I’ve never seen another piece of equipment with a micrometer stop. And when I say a micrometer, it is an actual micrometer. It looks like a giant machinist micrometer. And you can dial that depth of cut in, like you said, within a few tenths.

Yeah.

It allows us to do kiss-cutting on very fine liners that other people can’t. You mentioned earlier that you had a die maker tell you that, or a customer says it’s not possible to kiss cut on that material. We hear that all the time.

Yeah.

I did, we had a customer, this is probably two or three years ago. Come in and they were. I have no idea what the product was, but it was a piece, a really thin piece of glass that had a plastic laminate on top of it. And they said, can we kiss cut this laminate to the glass? And I kind of started laughing and I said, I have no idea, but I want to try it. You know, give me a piece. Let’s start there. And we did. And the moment I realized. I looked at one of our other sales guys and I said, this is an awesome demo. So, I went, and I got on Amazon. I ordered some 8 by 10 picture frames and took the glass out. Just straight, you know, flat glass. And we started doing demos and I’d put material in, set the press to 40 tons, and then say, okay, here’s what I’m going to do. I’m going to kiss-cut the material first without breaking the glass. Then I’m going to adjust that micrometer stop by the thickness of the paper. And I’m going to do another kit and I’m going to through cut it, but I’m not going to break the glass. And we can do it all day long.

Right. Yeah.

Then of course, one of the times that I’m showing somebody this I always take the glass out and break it with a hammer to show that it was a real glass. I had an Elon Musk moment where I hit it, and it didn’t break.

Ha ha.

They’re like, oh, of course not. There we go. I think he was demonstrating how tough the glass was on the Cybertruck. He said you can’t break it. He hits it and it just shatters. It was the opposite way for me.

Yeah. And broke it. Yeah.

Yeah, that’s great. That I’m sure you guys have a video out there of that. We’ll have to put a link to that in our bio or whatever.

Yeah. There’s one on YouTube. Yeah, there’s a lot of videos and I am in a lot of them. I have no idea why I keep telling everybody. I was like, I don’t know why this is the face they chose.

Well, we posted a very simple video that I just shot on my cell phone and posted on LinkedIn and Scott called me and he liked within minutes of me posting this video, like it wasn’t edited or anything. And he’s like, he goes, do you know how many calls I’ve gotten from that video? And I’m like, I have no idea. I just thought it was impressive that, you know, what we were doing, we could do. And he’s like, nobody else would dare to post something like that. And I’m like, why? He’s like, well, because one, they don’t want to know, give away any secrets. I’m like, well, I don’t think we’re giving away anything. We’re showing that we can do it. It took us a little bit to get there. But that was kind of an aha moment for me, you know, to get a call from Scott and brag about that video, I guess.

I remember it was probably seconds after he called you, that my phone blew up, he’s like, you got to check the video out. It was fantastic, it was awesome.

Yeah. And it is just a testimony to the machine, and it was very repeatable. Once we got set up, I think we had some learning curve to get the scrap matrix to pull off without breaking. And it was just trial, and error and we figured it out and documented it and we could set up and do it anytime now but, yeah.

Well, it’s always an interesting position. I’ve run into a few of our customers through the years that have that mentality of, I don’t need to be secretive about everything I do because if I can’t win the business, I can’t win the business, right?

Right.

And to me personally, I think it’s a pretty good demonstration of the faith you have in your company and what you’re doing. If you say, hey, look at this, this is what we can do for you.

Mm hmm. Sure. And I think if somebody is in the position that, they’re going to come to PRECO and buy their own machine, and that makes sense then, we’re only going to keep that business for so long anyway. Right. I mean, the ROI is there, and you know why not? We want to help the people who need help. And if we run a project for a company for X amount of time and they end up going and buying one of your machines, that’s awesome. Good for them. I mean, we did the same thing, because we were told that, you know, we couldn’t do a certain process, or they didn’t have the capability. And, I mean, that’s just the way things go. And if that’s what happens, that happens, I mean, we want to work with people that need help and want help. And we solve a problem for them. And hopefully, we will work with them for a lifetime. But if that’s not what happens that’s okay too. We’ve reached out especially in the beginning days, just to help fill capacity on the machine because we had so much, just contacting other converters and saying, hey, if you had any overflow work, we would love to help you out. We’ll sign an NDA. We’ll do whatever. We’re never going to go after the customer, but we would love to be able just to help and fill some of our capacity and it was kind of shocking to me how closed lip the converting industry is where they’re like, absolutely not. We would never do this. And then the fab world and the machining world, it’s like all of them, all these guys, they help each other out and all that. So that was a little different for me. We quoted a couple of jobs for a giant converter and we were able to run both products more efficiently than them. We could sell it to them, make our margin and they had less in it than if they were running it in-house and their engineers wanted to do it because they were just tired of fighting it. Upper management said, absolutely not. If this little company can figure it out, we’re going to figure it out. So, you know, that was kind of a disappointment that we didn’t win the business, but it was kind of a proud moment too.

For sure. Yeah, and I will say, you know, again, like converting is so diverse. There is sub sec of the converting industry that they are a little bit more communal helping. I know they ask inside of things that the gasket converters are very, I want to say communal, but they’re very open to helping each other out. And they’ll run jobs for each other.

Yeah.

There are only so many ways you can make a gasket. So, there’s not a whole lot of proprietary stuff going on there.

Sure.

But that’s one industry where they’re very much open-arm and willing to help. But yeah, the general converting guys. They tend to get a little closed-lipped because sometimes those guys are doing, well, as you know, I mean, you’re in that world too. Some of those projects come through are pretty high-tech, cutting-edge stuff, right?

Yeah, yeah, absolutely.

Or it’s going to end up in something like that.

Yeah, I don’t know. I like it. We enjoy it internally. We have a lot of fun with it. And it’s definitely a piece of our business that we’re putting a lot of energy into to grow. I think within the next year or so we will be looking to acquire a converter. So, if anyone’s listening to this, and you’re wanting to retire, there’s a tremendous amount of baby boomers out there that are in that position where they’re ready to go to Florida and do retirement things. So definitely interested in that.

Well, I can agree. I’m not a baby boomer, but I’m ready to go to Florida and do retirement things too.

Me too. Made me realize that even more when we were there yesterday and we get, you know, we get back late last night. We probably got back at two in the morning and surprisingly it wasn’t freezing. But I think tomorrow it’s going to be pretty damn cold here. So, yeah, I’m ready to spend more time down there as well.

Whereabouts in Florida were you?

Melbourne. India Atlantic specifically.

Okay, cool.

So yeah, like just South of Cocoa Beach. So, it was pretty cool. We got to see one rocket launch. I think there were three total while we were down there. One, we were sitting at dinner and there was so much cloud cover. You couldn’t see it. We were in Cocoa Beach eating dinner and you could feel it. Like you could just feel like the whole building’s rumbling.

UGH

And I’m like that is freaking awesome.

I’m super jealous. That’s one thing I’ve always wanted to see.

Yeah. And then, it is cool. We missed one. They delayed it, and we were out on the beach in Cocoa, and we were ready to watch it. And then we got a notification. We have this app that says, hey, it’s been delayed an hour. So, we’re like, okay, well, the girls wanted to go to Ron Jon’s and buy some sweaters and things like that. And we were going to kill time. And then suddenly you hear the rocket go off and you could feel like it. We were so sad we missed that one. Um, and it was clear. It would have been awesome as that night when I heard that the rocket launches at night were just incredible, especially that close. But they do a lot of them. I mean, I think there were at least four in Cape Canaveral. The other they’re all in the same general vicinity, Kennedy Space Center. There were probably four last week and then California SpaceX, they did a few. It’s amazing how many of those launches are going off. And you think when we were kids, there was like, maybe one a year or two a year or something. They’re shooting four or five a week. So.

Yep, and I guarantee you that on every one of those rockets, there were components that were converted, and I can’t guarantee it, but I bet folding money that there were parts that were cut on a PRECO perhaps.

Yeah, no, I would agree. Even then, you know, because there’s a lot of satellites on a lot of those rockets that, you know, they’re unmanned, they’re shooting the rocket off, they’re releasing satellites and then coming back. So, there’s a lot of parts cut on both of those. I know you guys have sold to NASA. I think quite a few machines to NASA, haven’t you?

I don’t know about NASA in particular.

Okay. I was, yeah, I was thinking there was a project at one time we were talking about.

Yeah, I don’t know fully, I’d have to go back and look. I don’t know, we’ve been with so many different industries and companies. I don’t know about NASA specifically, but I’d have to go back and look at that. Yeah. You know, it’s interesting. I talked to a guy. You’re going back to the gasket industry. I was down at the gasket fabricator show in Orlando two weeks ago. And I was talking to a guy that had a gasket company in, you want to talk about kind of middle of the nowhere. He was up near, way up in the northeast of Canada. Way up there. But he does like really custom, almost one-off gaskets. He was telling me it’s not uncommon for him to sell a single gasket for like $2,800.

Oh wow.

It’s like, woof! And that’s the kind of stuff he’s doing, you know, stuff like that.

Wow. Yeah. I like that. That’s something that we are not good at right now is the low volume of things and we need to be better at that. And I know that we’ll have companies and they want to run 50 or 100. For us to do that, it’s pretty difficult. I think maybe I’m approaching it wrong and you can tell me that. But when we do that, if we get a blanket order, we will run 50 or a hundred for the same prices, you know, whatever the volume is. But if somebody’s just in at a stage where they’re not able to commit to those bigger volumes. Between material and then set up and all the other things that eat up an entire day on that machine. So, we price that way. And I’m not sure if we’re doing that properly right now. So, we need to be better and figure out the lower volume stuff. And I don’t know if that’s a clicker press or laser or what the appropriate way to go about that is yet.

Yeah, it’s kind of a tricky one. It depends. I’ve got customers that do very low-run jobs. I got one in particular. Their average part order is 25 to 150 parts.

Wow.

They’ll do a billion setups throughout the day. It’s all kinds of low-hanging fruit stuff, not difficult to cut, anything like that.

Right.

They’ll turn and burn all day long and do them. Laser is always great for that, but the laser does some amazing things, quick changeover, and no tooling is part of that. But the lasers also come with a fairly significant price tag on them.

Sure.

But it’s one of those things you can do, but it comes down to, is the material easy? Do I have to do a boatload setup on it? If you’ve got some kiss cutting that’s pretty fine on it or you’re doing a multi-height die where you’re going to have to tune it in for the kiss cut and the through cut. Yeah, you could potentially run into that. But it’s done, yeah.

Yeah, maybe we will explore that together here soon because I do think that we’re missing out on the lower-volume stuff that could potentially turn into higher-volume stuff.

Yeah, for sure.

So, we kind of push them out the door to somebody who could do the lower volume at a better price than we can. And they may never come back because that company could do the lower volume stuff and the big, the higher volume stuff and they have already created that relationship.

Yeah, yeah. Well, and like you said too, short-run stuff, the clicker, you know, it’s an inexpensive press and pretty well suited for doing small little-short runner prototyping stuff.

Sure.

But yeah, like you said, you never know what a customer could turn into, you know.

Yeah, absolutely. And I’m like you, I have a hard time saying no. The reason why we own one of your presses, I guess. So awesome, man. Well, I appreciate it. I know that you’re extremely busy and with our little glitch, we’ve been on here for a good amount of time.

And why don’t you tell everyone how they can get ahold of you? Also, put some links and the description and we will do a blog. We’ll take this entire podcast, convert it to text and do a blog with it. Website, how they get ahold of your phone number, and cool YouTube videos that you want to share. We can always put those on and all that fun stuff.

Yeah, I completely appreciate it. Let me say again, Dustin, thank you so much for having me on this. This is awesome. So, our company website, we’re PRECO LLC, and our website is www.precollc.com. You can contact me there, or it’s my name, Zach Haddock, it’s Z. Haddock, H-A-D-D-O-C-K, at precollc.com(zhaddock@precollc.com).

Yeah.

I always preface this too, don’t hesitate to reach out to me just because you’re not necessarily looking for equipment. If you’ve just got a die-cutting question, reach out to me. I’m happy to help. I serve on the IADD, which is the International Association of Die Makers and Die Cutters on their technical team. And we advise people with die-cutting issues. So don’t ever hesitate to reach out. Always happy to help. Dustin, you can attest to this. I kind of like a talk and a shop. So, it’s, yeah, right.

Yeah. That’s why we’re here. Right? Yeah. We could talk for a lot longer. So, you know, maybe we do a follow-up, and we do something more technical and dive into a little more granular in-the-weeds type of conversation.

Yeah, that’d be awesome. And then, our YouTube website, I’ve got a full list of technical videos, how-to on there, as well as just stuff about PRECO and what we do.

Yeah. You guys do a great job with your videos. I mean, they’re just short, sweet, get to the point. My favorite ones are the old-school ones where there’s people smoking around the precedent.

Yeah, people like full-blown 80s mullets and Jeffrey Dombard glasses walking around.

Oh yeah. Yeah. Those are still, I mean, they’re applicable to today. I mean, some of those are, they’re great. And you kind of chuckle about them and that we had some video, not MCMILLANCO, but companies that I worked out like there were pictures on the website of everyone’s got a cigarette in their hand, like leaning up against the desk, smoking inside. It’s like, man, times have changed. Thank goodness.

Yeah, when I moved into my office, in one of the counter covers, there was a bunch of ashtrays. Yeah.

Yeah. The place I worked at had a fan in the ceiling because they would smoke in this tiny little conference room, and it would suck all the smoke out. So, I’m glad those days are over. Yeah, but awesome, man. Well, thank you so much for coming on. I appreciate it. It’s always fun. And you know, we’ll keep plugging away together.

Yeah, likewise. Take care.

Yep. Thanks man. Bye.

For more insightful conversations like this, visit MFGMonkey.com. Listen to this episode and many others on Apple Podcasts, Spotify, or your favorite podcast platform.