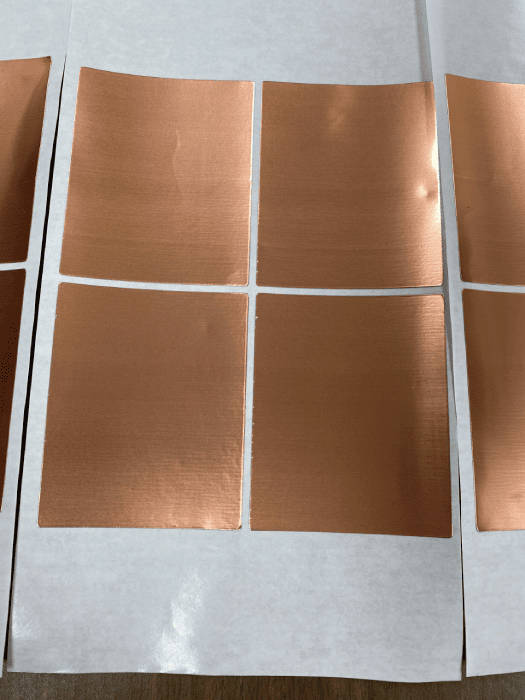

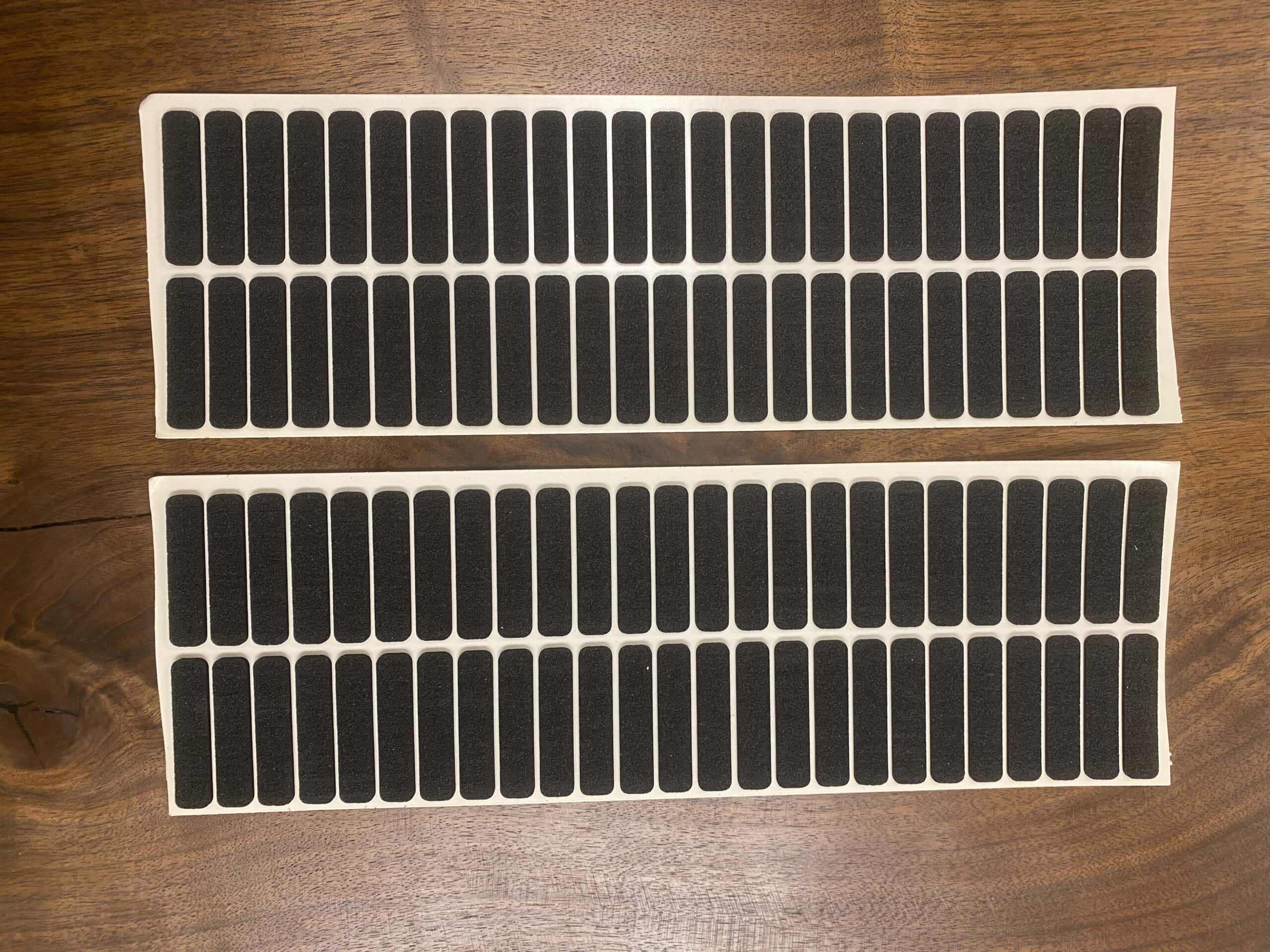

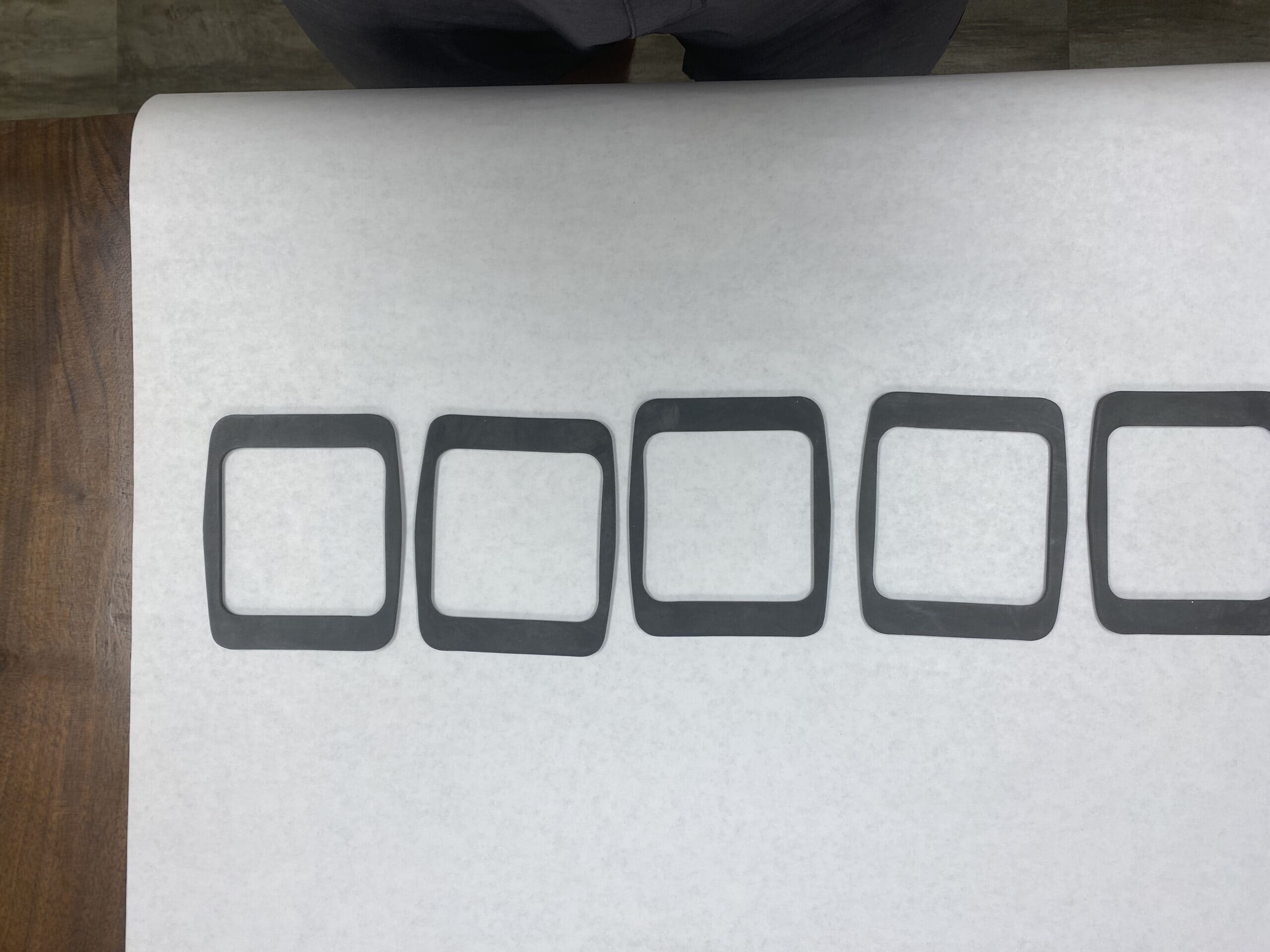

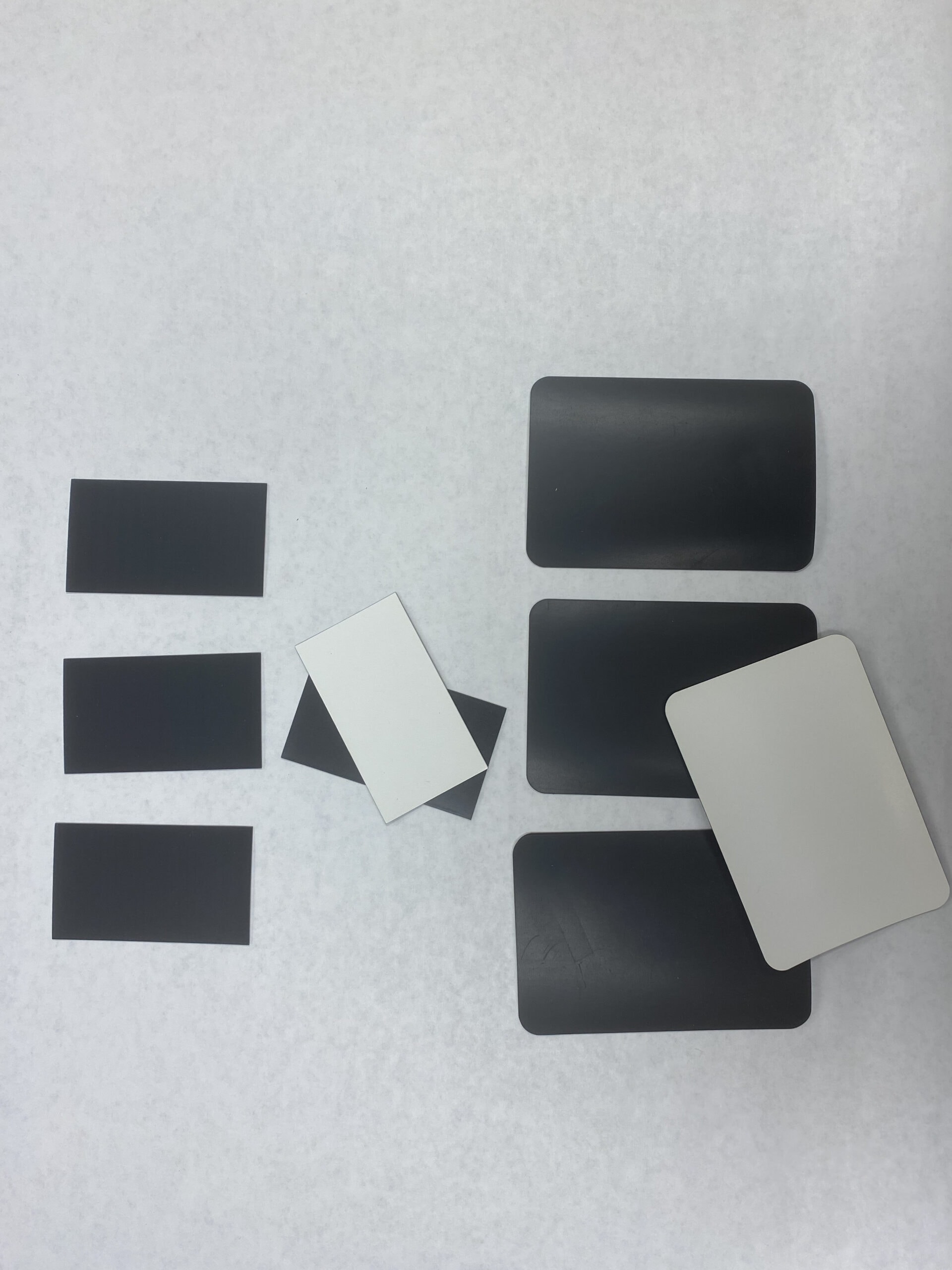

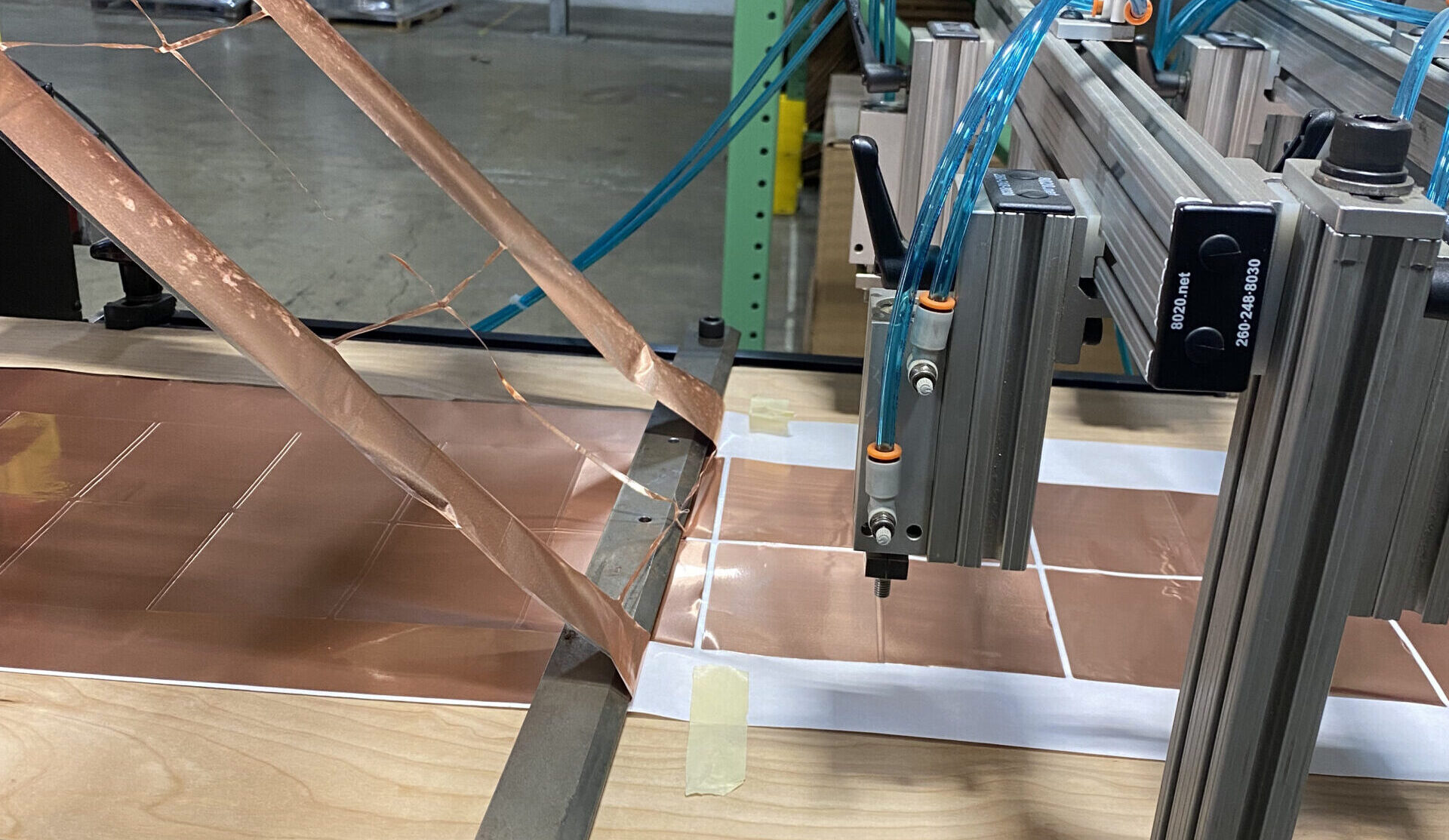

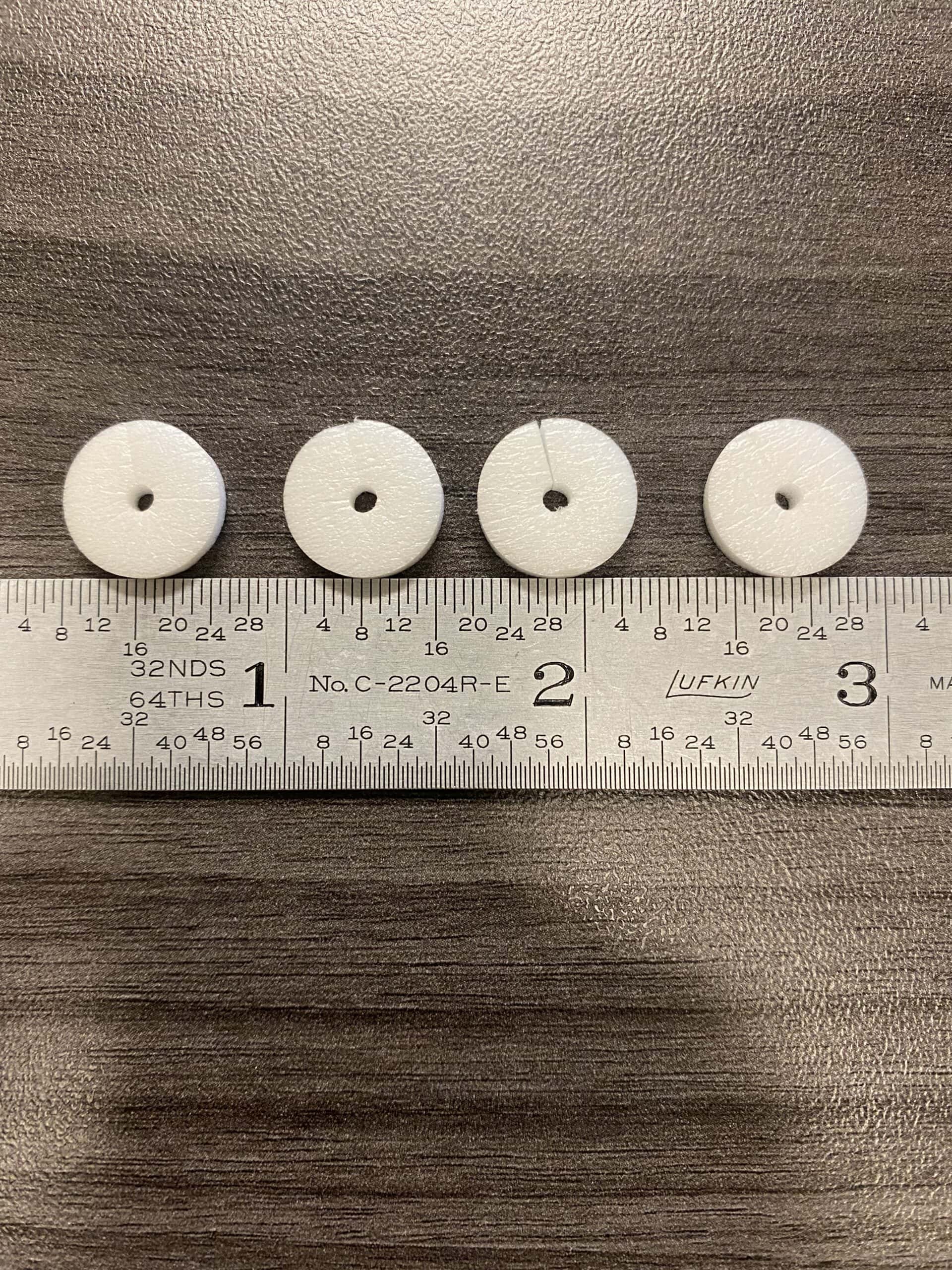

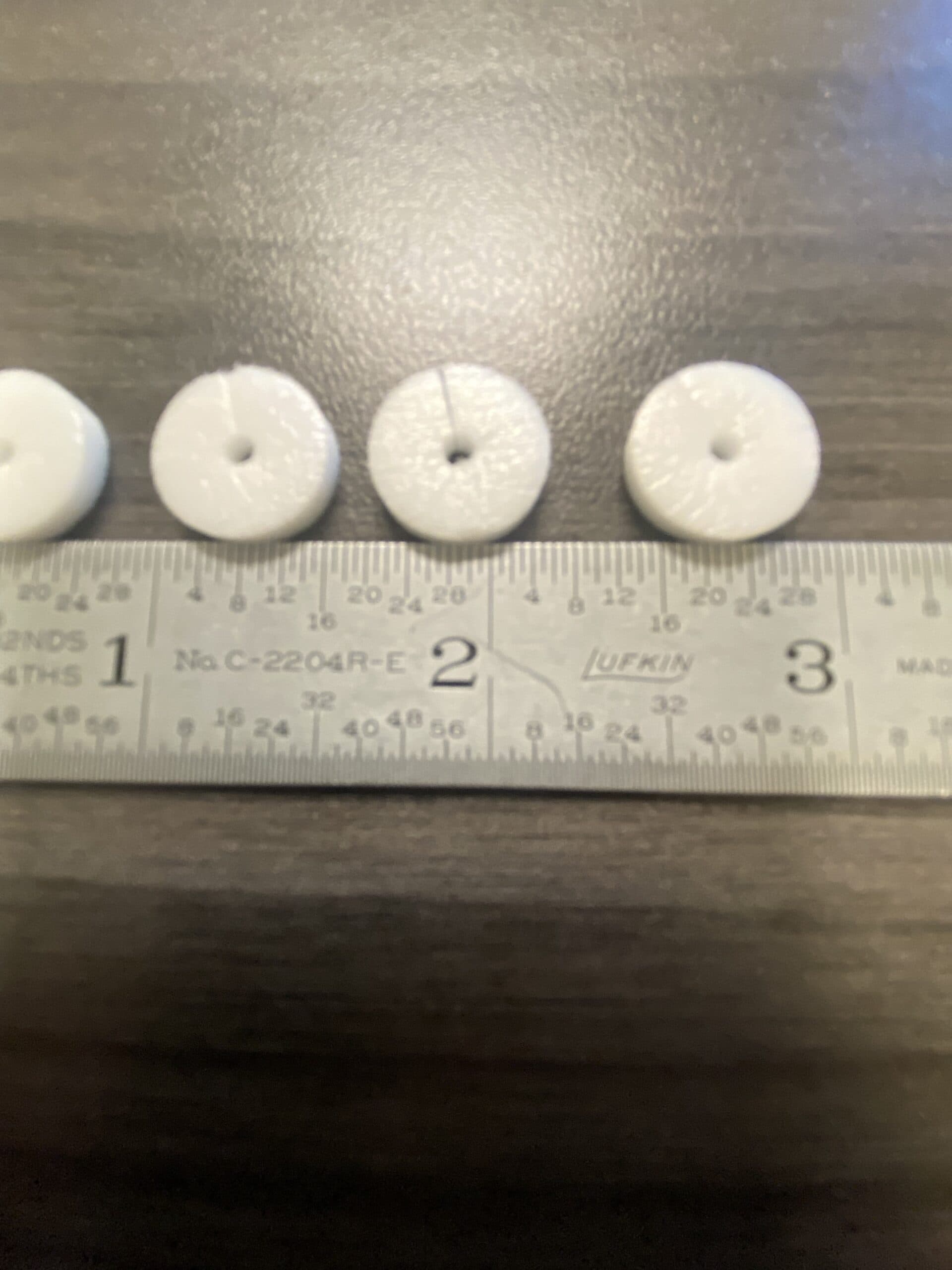

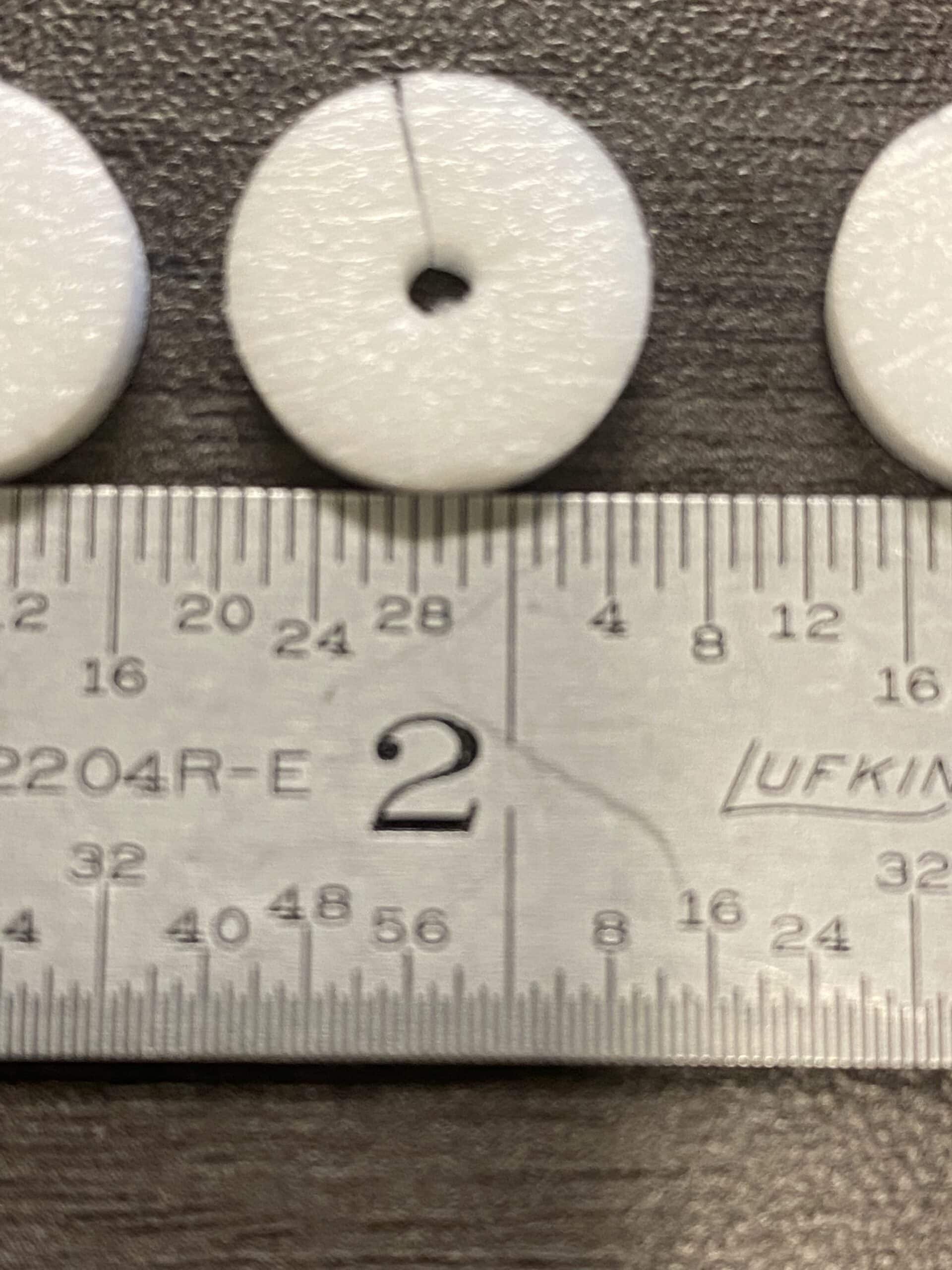

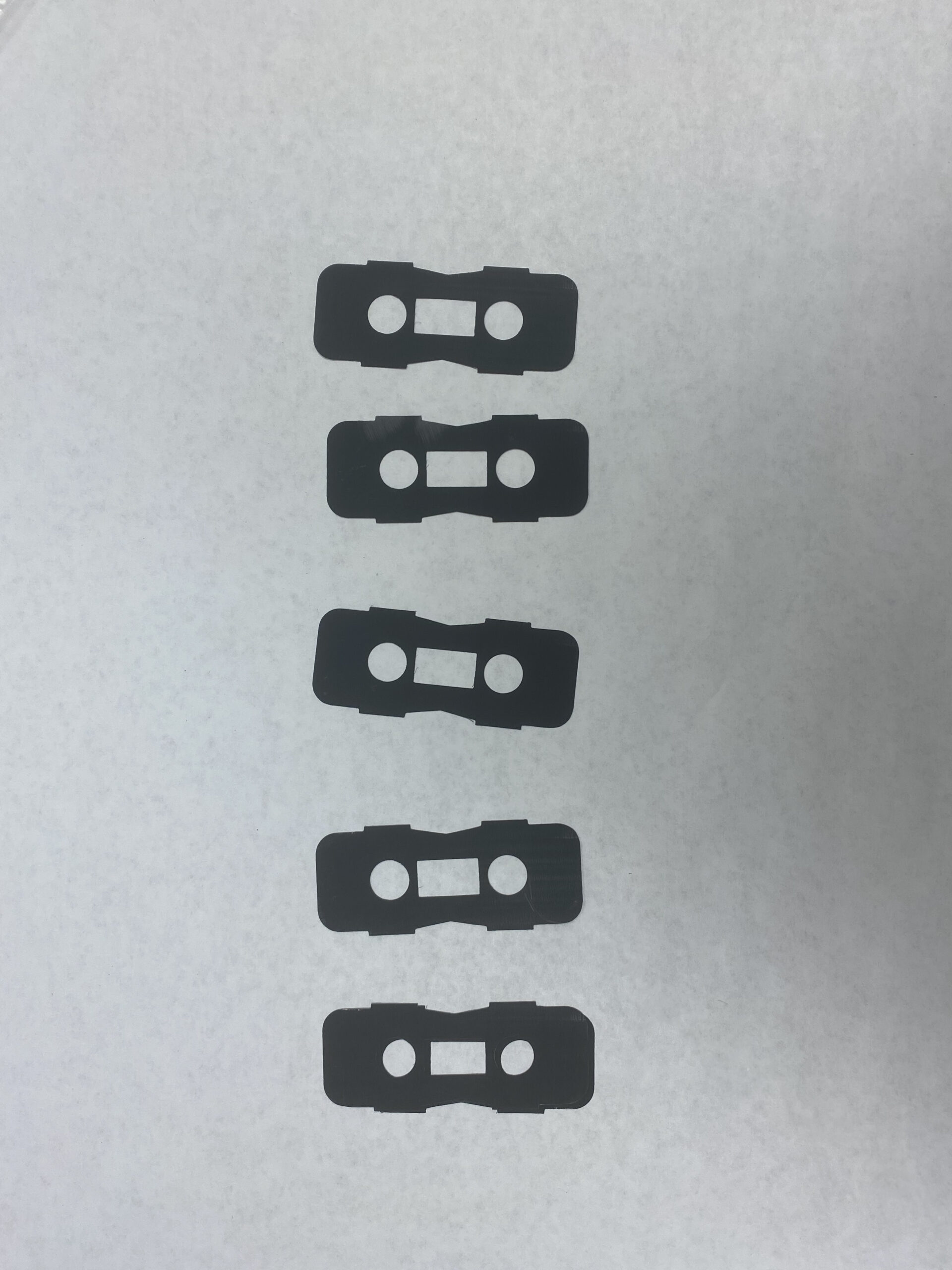

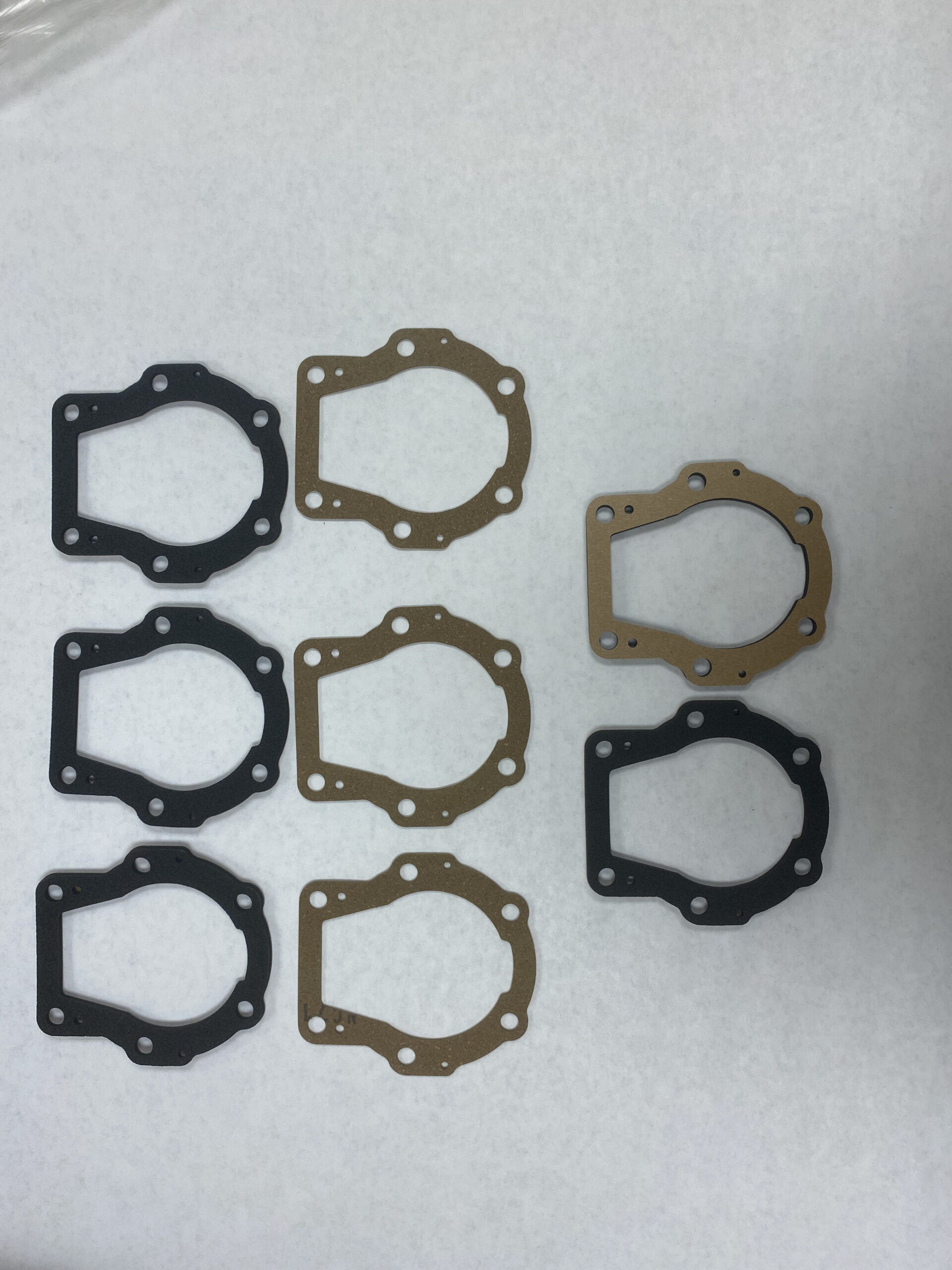

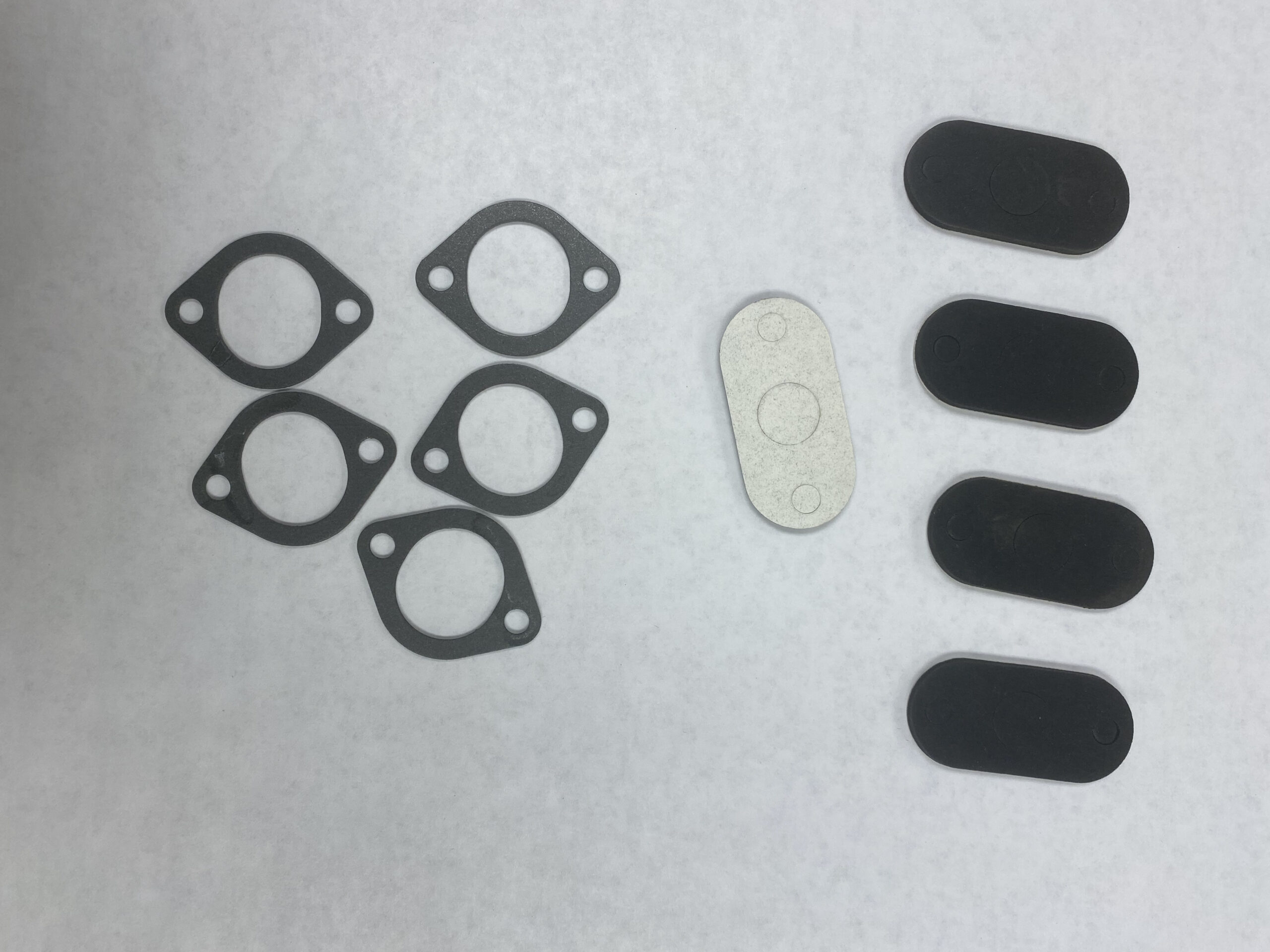

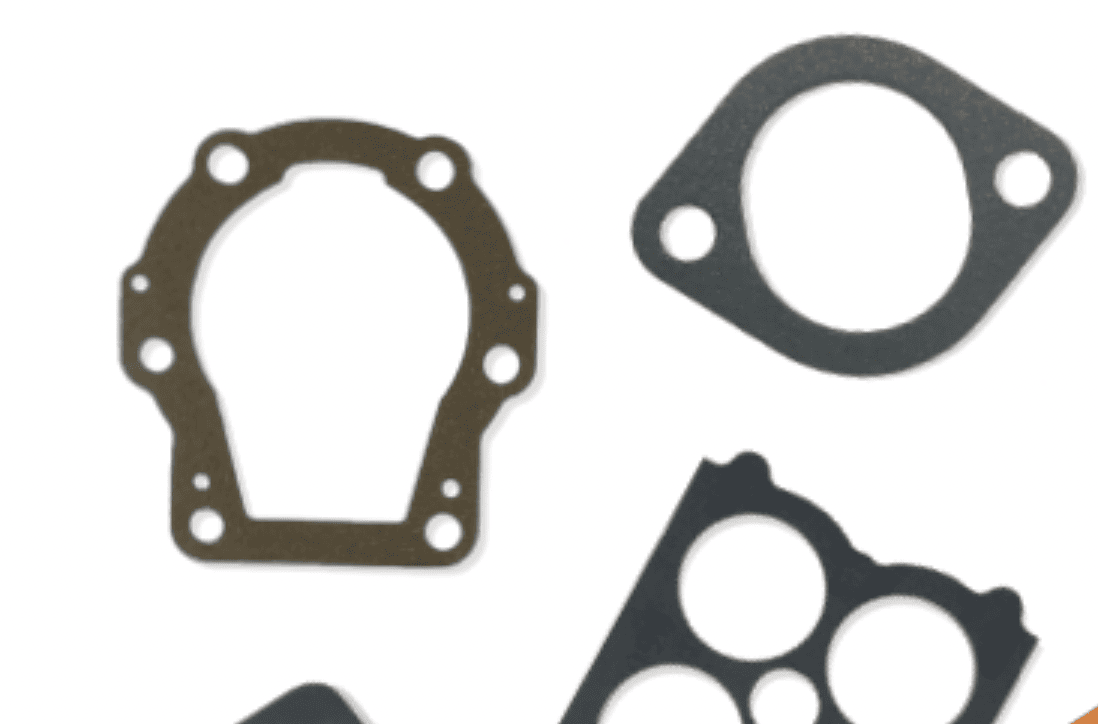

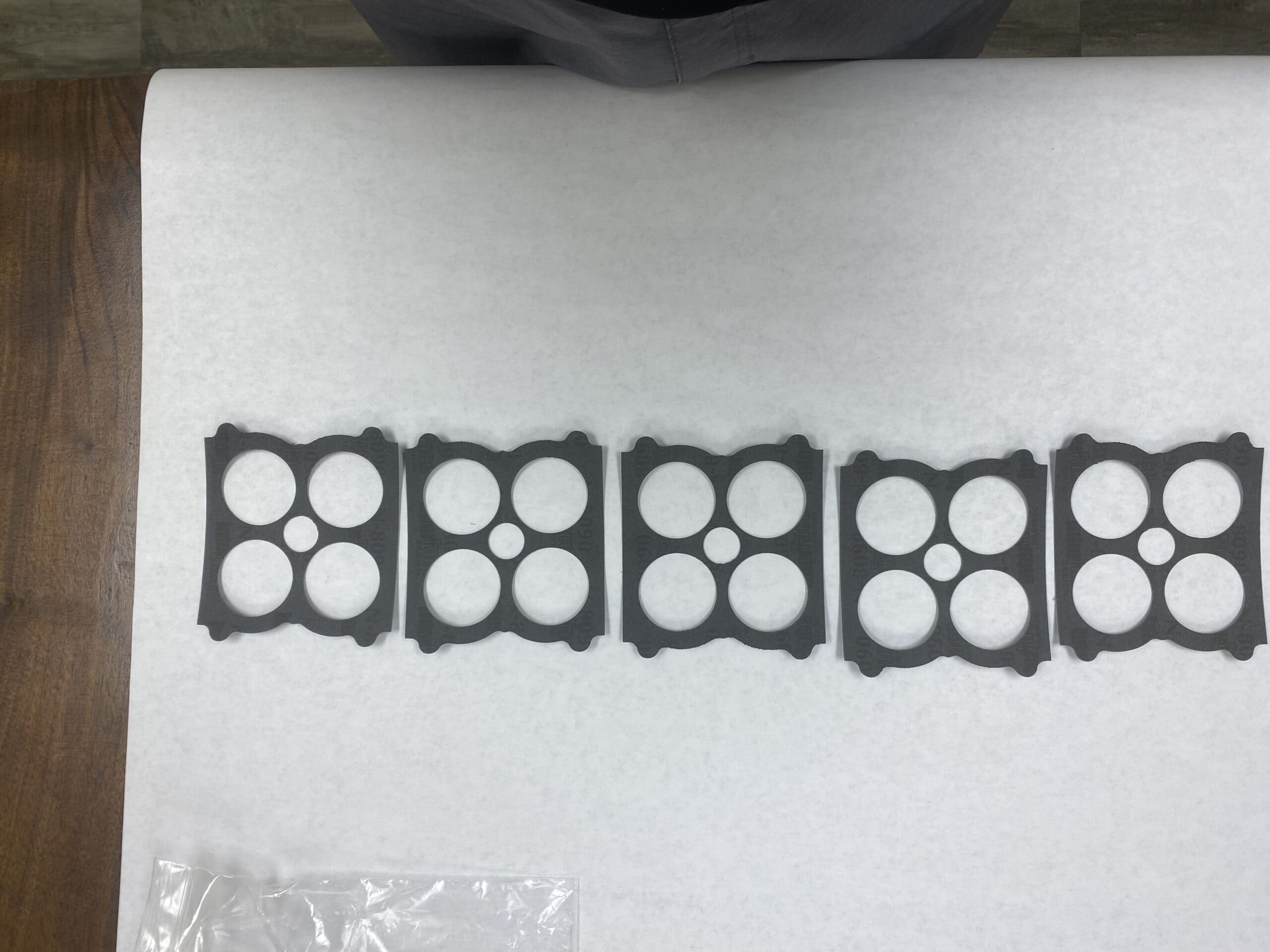

Laminating, Die Cutting, and Kiss Cutting

MCMILLANCO is now offering a wide variety of services to be used for our new machine. This new in-house machine is used widely for the precise lamination of electronics and medical parts, as well as for simpler mass-produced graphical promotions and more — die cutting, also known as kiss cutting. Our machine creates several types of lamination systems, based on registration tolerance requirement, the need for selecting between in-line or freestanding construction, and the choice of pressure-sensitive or heated adhesive methods. This new die cutting machine will allow us to fulfill a broader selection of customer needs with a decreased turnaround time. This device will further push MCMILLANCO and its partners to the forefront of the manufacturing industry through our kiss cutting services.

View our Kiss Cutting Blogs: